The electronics industry is developing rapidly today, and electronic components are widely used. Aluminum electrolytic capacitor are a commonly used electronic component and are widely used in electronic devices. In this article, we will interpret aluminum electrolytic capacitors from different perspectives to help you better understand their characteristics and applications.

1.What are aluminum electrolytic capacitors?

Aluminum electrolytic capacitors are capacitors that use aluminum foil as electrodes and aluminum oxide film as the dielectric. Due to the high insulation strength of the oxide film on the aluminum foil surface, aluminum electrolytic capacitors can achieve a combination of high capacitance and high voltage. In electronic circuits, aluminum electrolytic capacitors are usually used in DC circuits for filtering and decoupling, as well as in high-frequency circuits such as computer motherboards.

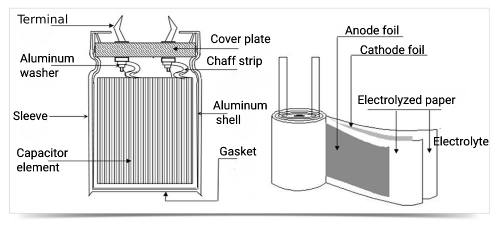

2.The structure of aluminum electrolytic capacitors

The basic structure of an aluminum electrolytic capacitor consists of two electrodes, an electrolyte, and an insulator. One electrode is made of aluminum foil, and the other is a metal foil with a conductive coating. There is an electrolyte between these two electrodes, usually aluminum sulfate. The insulator is a special material used to prevent direct contact between the electrodes.

3.The general production process of aluminum electrolytic capacitors

Step 1: Etching

To enhance the contact area between the aluminum foil and the electrolyte, the aluminum foil is electrochemically etched to form a rough and porous surface, thereby increasing its surface area.

Step 2: Anodizing

Following the galvanic etching, a chemical process is employed to convert the aluminum foil’s surface into aluminum oxide, which acts as the dielectric of aluminum electrolytic capacitors.

Step 3: Cutting

Before manufacturing a specific type of electrolytic capacitor, the aluminum foil is cut into varying widths based on its size.

Step 4: Riveting and Winding

The aluminum foil is nailed with guide pins, followed by winding positive foil, electrolytic paper, negative foil, and so on.

Step 5: Dipping

Once the electrolytic paper is wound, the electrolyte is poured in, allowing it to be impregnated onto the electrolytic paper.

Step 6: Sealing

The core package of the electrolytic capacitor is enclosed within an aluminum container, and the container’s opening is sealed using a rubber plug or a resin plate to prevent the electrolyte from evaporating.

Step 7: Aging

This process involves subjecting the capacitor to a DC voltage greater than the rated voltage but less than the original anodizing voltage of the aluminum foil, which repairs and screens any faulty products.

4.Characteristics

- High capacitance: Aluminum electrolytic capacitors have a large capacitance value, typically ranging from several microfarads to several hundred millifarads, to meet the requirements of different circuits.

- High voltage: Aluminum electrolytic capacitors can achieve high operating voltages, typically ranging from several hundred volts to several hundred volts, making them suitable for high-voltage DC circuits.

- Small size: Aluminum electrolytic capacitors have a small volume and weight, making them suitable for use in integrated circuits and microelectronic devices.

- Affordable price: Aluminum electrolytic capacitors are relatively inexpensive and easy to obtain, which is one of the reasons why they are widely used.

5.Applications

Aluminum electrolytic capacitors have a wide range of applications in electronic circuits, such as filtering circuits, decoupling circuits, oscillation circuits, voltage regulation circuits, and amplification circuits. Here are a few examples of their applications:

- Power supply filtering circuit: Aluminum electrolytic capacitors can be used as the filtering capacitor in power supply filtering circuits, filtering out ripple signals in the power supply to make the output smoother, reduce output fluctuations, and improve power supply stability.

- Circuit decoupling: Aluminum electrolytic capacitors can be used as the coupling capacitor in circuit decoupling to separate DC components from AC components, isolate DC and AC circuits, and improve circuit stability and reliability.

- Audio amplifier circuit: Aluminum electrolytic capacitors can be used as coupling capacitors and limiting capacitors in audio amplifier circuits to amplify and limit sound signals.

If you have needs in capacitors, please contact us now!

[contact-form-7 id=”5″ title=”Contact form 1″]