Xuansn Capacitor

Company Profile

Company Profile

In June 2004, we started our electrolytic capacitor.Xuansn electrolytic capacitor is also about to be born.

In October 2012, we established Xuansn Capacitor to expand our foreign business. And our mission is to help the costomer to save time and cost to get the suitable capacitor that have good quality and good price.

After 19 years of development, the current factory covers an area of 40,000 square meters, 180 automatic production lines. And have our own industrial park, developed a pragmatic and professional management team.

The product has evolved from a single radial aluminum electrolytic capacitor into a variety of products, including chip aluminum electrolytic capacitor, solid state electrolytic capacitor, snap-on capacitor, screw electrolytic capacitor, metallized polypropylene film capacitor, metallized polyester film capacitor, X2 fuse capacitor, Y capacitor, ceramic DISC capacitors, SMD ceramic capacitors.

XUANSN EQUIPMENTS:

XUANSN TEAMS:

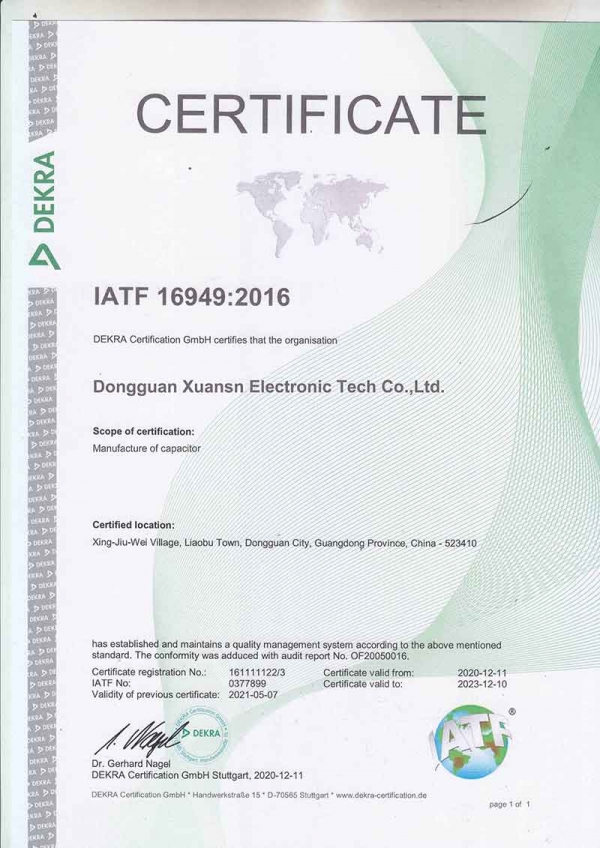

Certificates:

FAQ

Q1:

What consequences are expected when a voltage exceeding the rated voltage is applied to an aluminum electrolytic capacitor?

A1:

On the anode foil of an aluminum electrolytic capacitor, an oxide film capable of withstanding the rated voltage even if it is continuously applied at the maximum operating temperature.

In the event that a voltage exceeding the withstand voltage of this oxide film (overvoltage) is applied, the anode foil of the aluminum electrolytic capacitor will form an oxide film equivalent to the applied voltage. The reaction will generate gases, which will increase the pressure in the condenser. Depending on the characteristics of the capacitor, this will lead to a decrease in electrostatic capacitance and an increase in the tangent of the loss angle. The higher the applied voltage and the higher the ambient temperature, the more gases are released and the higher the internal pressure. Sometimes this can lead to such phenomena as swelling of the sealing material (rubber packing) and further to the operation of the safety device (slipping of the rubber packing in products without a safety device). Therefore, avoid using a capacitor in a circuit where more than rated voltage can be applied to it.

The modes of structural destruction when exposed to overvoltage are as follows:

(1) Open

The safety device is triggered (or the rubber seal slips out) and the liquid electrolyte in the capacitor spills out, causing it to dry out and finally open.

(2) Short circuit

If a voltage is applied that exceeds the withstand voltage of the anode foil, liquid electrolyte and release paper, and it is no longer possible to maintain the insulation, dielectric breakdown will occur, resulting in a short circuit.

Q2:

What consequences are expected when a voltage of reverse polarity is applied to an aluminum electrolytic capacitor?

A2:

In the case where a voltage exceeding the withstand voltage is applied to the cathode foil of the polar aluminum electrolytic capacitor, a current flows to electrolyze the water contained in the liquid electrolyte. The oxygen generated by this electrolysis will then react with the cathode foil to form an oxide film on the surface of the cathode foil (chemical conversion coating of the cathode foil). As a result of this reaction, the capacity of the cathode foil will decrease. Since the capacitance of the capacitor is a combination of the capacities of the anode and cathode foil, this can lead to a decrease in the capacitance of the capacitor and a further increase in the loss tangent (tan δ).

In addition, this reaction will generate gases in the condenser, which will increase the internal pressure. The higher the applied voltage and the higher the ambient temperature, the more gases are released. Depending on the applied voltage and temperature, this can sometimes lead to phenomena such as swelling of the rubber packing of the capacitor, and sometimes to triggering of the safety device or slipping of the rubber packing in products without a safety device. Therefore, avoid using a capacitor in a circuit where a reverse polarity capacitor or reverse voltage can be applied.

Sincerely invite you to visit our company!