The application of supercapacitor positioning is similar to that of the battery, mainly as a power source, but its duration is much shorter than that of the battery, and its discharge capacity is much higher than that of the battery. Therefore, the application of supercapacitor is probably a blank application space between batteries and electrolytic capacitors. The best application range is the discharge time between 0.1s and 30s.

1 Supercapacitors improve car starting performance

Supercapacitors, also known as ultra-capacitors, are energy storage devices that offer high power density, fast charge/discharge cycles, and long cycle life. Automotive application of supercapacitor can be combined with traditional lead-acid batteries to improve vehicle starting performance.

During the engine start-up process, the starter motor draws a large amount of current from the battery, causing a rapid voltage drop at the battery terminals. By adding a supercapacitor in parallel with the battery, the voltage drop during start-up can be reduced, which increases the available power to the starter motor and improves the engine starting performance. This is especially useful in situations where frequent starts are required, such as at stop lights or in heavy traffic.

Supercapacitors can also be used to improve engine starting performance in cold weather conditions. At low temperatures, the battery’s available power decreases, which can make it difficult to start the engine. However, the high power density and fast charge/discharge cycles of supercapacitors make them well-suited for providing the additional power needed to start an engine in cold weather.

In addition to improving starting performance, supercapacitors can also be used to capture and store energy during regenerative braking, which can then be used to power electrical accessories or assist the engine during acceleration. Overall, the use of supercapacitors in automotive applications offers a promising avenue for improving vehicle performance and efficiency.Therefore, the application of supercapacitor in automobiles is very critical and important

1.1 Problems with the battery

The battery is a crucial component in cars and its performance directly affects the starting of the vehicle. The current required for starting the engine is very high, leading to a significant drop in the battery voltage during the start-up process. This sudden drop in voltage causes strong electromagnetic interference that can affect the electrical equipment in the car, potentially leading to malfunction or damage. Due to its size and weight, increasing the battery capacity is not a practical solution. Therefore, using a supercapacitor in parallel with the battery can effectively solve this problem.

1.2 The combination of supercapacitor and battery improves the starting performance of automobiles

1.2.1 Application of supercapacitor-Improvement of electrical performance

The selection of supercapacitors mainly depends on the equivalent series resistance of the supercapacitor. In the application of small cars, the total equivalent series resistance can be used below 10mΩ, while for heavy-duty vehicles, it is hoped to choose 5mΩ or even below 2mΩ. If it can reach 1mΩ then It is even more desirable.

The current and output power waveforms are shown in Figure 6.26. Compared with Figure 6.24, the voltage drop at the moment of starting is increased from 3.2V to 7.2V when only the battery is used; the starting current is increased from 560A to 1200A; the output power of the power supply at the moment of starting is increased from 2kW to 8.7kW; the steady voltage during starting is increased from 7V Increased to 9.4V; the steady current of the starting process increased from 280A to 440A; the steady output power of the power supply during the starting process increased from 2.44kw to 4.12kW.

1.2.2 Improvement of startup performance

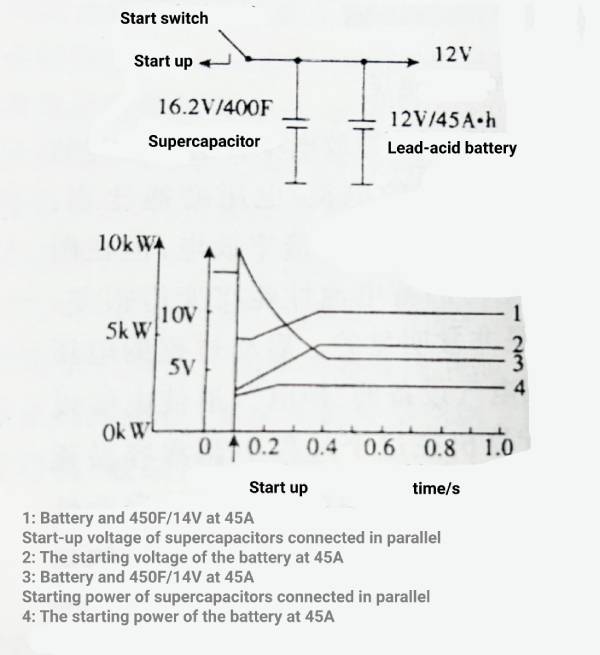

Using a supercapacitor in parallel with the battery can improve the starting performance of the car. Taking a car equipped with a 19L diesel engine as an example, a 250F/16.2V supercapacitor is used in parallel with a 12V, 45A battery, and it can start smoothly at minus 10 degrees Celsius. Although the battery can be started alone, when the supercapacitor is used in parallel with the battery, the starting speed and performance have been significantly improved. The parallel connection of supercapacitors can also increase the output power so that the starting speed can be increased from 300/min to 450/min. In addition, the use of supercapacitors is very meaningful in low-temperature environments, because the performance of the battery will be greatly reduced, which may lead to failure to start normally or multiple starts. When using a supercapacitor in parallel with the battery, it only needs one ignition to start successfully.

1.2.3 Improvement of battery application status

When the supercapacitor is connected in parallel with the battery since the equivalent series resistance of the supercapacitor is much lower than the internal resistance of the battery, most of the starting current is provided by the supercapacitor, which improves the stable voltage during the starting process. This not only effectively reduces the polarization of the battery plate and prolongs the battery’s service life but also frequent starting will no longer have a great impact on the life of the battery. Therefore, from the perspective of energy saving, the engine can be turned off when the red light is stopped and then restarted when the green light is turned on. Especially when the bus stops at the station and turns off the engine, and restarts when leaving the station, it will not have too much impact on the life of the battery.

2 Application of supercapacitor in hybrid electric vehicles and electric vehicles

2.1 Series-Parallel Hybrid Technology

There are many stops for urban buses, and each station needs to stop, start, and accelerate. Frequent braking and start-up acceleration are its biggest characteristics when encountering traffic lights. Due to the characteristics of the internal combustion engine, not only the fuel consumption is high when starting, but also the exhaust emissions are the largest. When accelerating, because the engine works in a high power output state, its fuel consumption and exhaust emissions are also very large. However, during braking, the kinetic energy obtained by accelerating the engine is converted into heat energy by braking and consumed in vain. According to the above, the fuel consumption and exhaust emissions of urban buses are very high. To reduce fuel consumption and exhaust emissions, the best way is to use hybrid technology or fuel cell power technology.

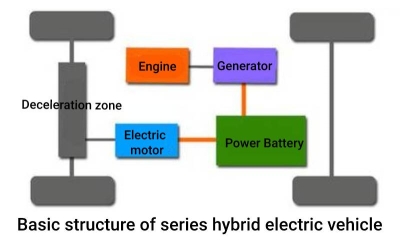

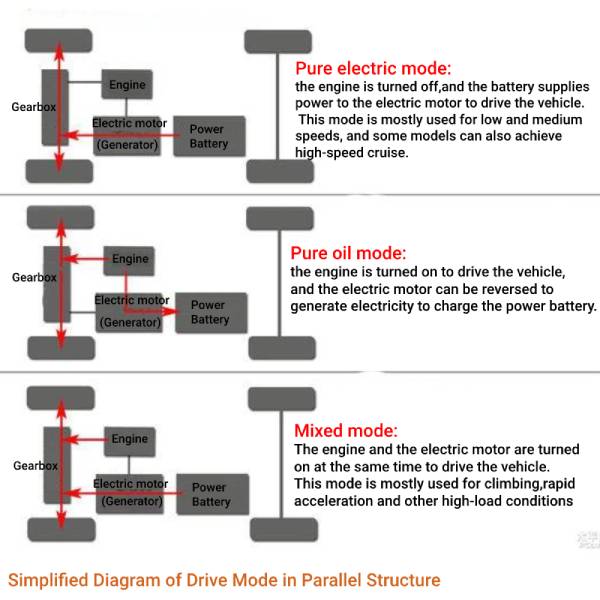

The connection between the electric drive and the internal combustion engine of a hybrid vehicle can be divided into series hybrid technology and parallel hybrid technology. The basic structure of the series hybrid technology is shown in 6.27, and the parallel hybrid technology is shown in Figure 6.28.

In hybrid electric vehicles, two types of hybrid technology are used: series hybrid and parallel hybrid. In a series hybrid, the wheels are powered solely by the drive motor, which is fed by a diesel engine operating at a constant speed to drive a synchronous generator and an energy storage unit (such as a supercapacitor) through a two-way power conversion converter circuit. This setup allows the drive motor to receive power from both the diesel engine and the energy storage unit. In contrast, in a parallel hybrid, the internal combustion engine and the drive motor share the responsibility of powering the wheels. The electric motor is used to drive the vehicle at low speeds, while the internal combustion engine takes over at higher speeds and under heavy load conditions. Both types of hybrid technology can help reduce the required power output of the drive motor and the energy storage unit, leading to more efficient and cost-effective vehicles.

For example, the electric energy provided by the 336V/12F supercapacitor bank is enough to drive a 40kW electric motor with a current of 300A for the 20s, which can easily complete the electric start and electric auxiliary acceleration functions of hybrid vehicles. Not only that but the drive motor can also be used to work in the power generation feedback state to recover the kinetic energy of braking and convert it into electrical energy and store it in the supercapacitor.

The control method can be as follows: when the car starts, the speed is lower than 20km/h, the supercapacitor is discharged when the output power of the diesel engine is less than a certain power value under the acceleration state; when the car is braking, the braking energy (charged) is transferred to the drive motor converted into electrical energy to charge the supercapacitor. Due to the existence of the supercapacitor energy storage unit, both the diesel engine and the storage unit can always run in an efficient state. As a result, fuel consumption can be reduced by more than 20%. In this way, the total energy demand of the city center can be reduced by about 18%. The application of supercapacitor is not limited to hybrid buses, they are also suitable for frequent acceleration and braking cycles of all subways and various cars, which can save a lot of energy.

The application of supercapacitor is particularly beneficial in urban traffic.The use of braking energy feedback in motor vehicles, particularly in urban traffic, has significant benefits. During stop-and-go traffic or when stuck at traffic lights, vehicles frequently brake and accelerate, and the kinetic energy generated during braking is usually dissipated as heat energy, leading to increased energy loss. To reduce environmental pollution, it is essential to save energy during braking and reuse it. This is particularly beneficial for hybrid vehicles using internal combustion engines, where AC motors can be used as brake generators.

Supercapacitors are ideal devices for these applications due to their high energy storage capacity and strong ability to handle current. Unlike traditional lead-acid batteries, which have limited charge and discharge life, supercapacitors can be charged frequently and rapidly, and they can be discharged to 0V with a time constant of only about 2s without any risk of fault.

Supercapacitors have capacitance values in the thousands of Farads, making them highly efficient at storing energy generated in a short amount of time and releasing it efficiently. In the following example, the cost-effectiveness and rationality of supercapacitors are illustrated.

For example, a 2-ton car stops at a red light. In this process, all the kinetic energy is converted into electric energy and stored in the supercapacitor. When braking, the car goes from a speed of 50km/h until the final speed becomes 0. The following calculation shows that the 19.3kJ energy generated during braking (supercapacitor voltage from 25~46V during constant current braking) stored in the capacitor can make the capacitive energy of the capacitor reach 260F.

The kinetic energy of the car

Ek=0.5m·V2

In the formula, mass m=2000kg, speed v=50km/h=13.89m/s, braking energy (vehicle kinetic energy) Ek is 193kJ.

Capacitors required to store braking energy

E1=0.5C·(VE2-VA2)

In the formula, VE is the initial charging voltage of the capacitor, and VA is the final charging voltage of the capacitor. When E = 193kJ, the required capacitance is 260F.

The corresponding braking current is

△Q=I·△t=C·△V

When △t=10s, △V=21V, Ic=546A

From the above calculations, a supercapacitor suitable for this application requires a capacitance of 260F and a surge voltage of 46V. It can be formed by connecting 18 5000F/2.7V supercapacitors in series.

During post-braking acceleration, the supercar starts to discharge and the voltage drops, discharging from 46V to 25V at a constant current of 546A. In terms of the energy loss in the above case, the supercapacitor can still provide an additional 14kW of power for 10s, which makes the total efficiency 72%, because the acceleration power of 7.5kW can be maintained for the 20s, and the capacitance loss is very low, making the overall efficiency increase to 78%. This idea can naturally be applied to all similar braking processes, but the braking process should be less than 1min. This example shows that the application of supercapacitor can improve the range and acceleration of motor vehicles.

Applying a supercapacitor-based regenerative braking device to a diesel-driven bus can reduce fuel consumption by 25% and reduce exhaust emissions by about 20%. At the same time, the life of the supercapacitor can be the same as or higher than that of the car itself.

It should be noted that the electric part of the hybrid vehicle only provides auxiliary power for a short time, such as a few minutes or ten minutes. Therefore, hybrid electric vehicles are suitable for urban road applications where high-speed continuous driving or frequent braking and starting are not possible. If it is continuous driving on the highway, the battery or supercapacitor at this time will not be able to provide continuous power. At this time, the energy-saving effect of the hybrid vehicle will be negative, because the charging of the battery or supercapacitor requires the engine to provide power, and the energy efficiency at this time is not as good as that of the mains charging or the engine directly providing power.

In electric vehicles, fuel cells have gradually become one of the electric energy supply methods for electric vehicles. Due to the relatively slow response speed of fuel cells, a short-term power balance device is required, and the ideal device is a supercapacitor. The supercapacitor can absorb or release the redundant or insufficient power part of the fuel cell when the power changes. It should be noted that to reduce the fuel cell cost of fuel cell electric vehicles, an additional power source (such as a storage battery) and a fuel cell combination are required. Part of it needs to be provided by the battery (such as 20% of the power).

3 Application of supercapacitor-Supercapacitor electric vehicles

The application of supercapacitor in electric vehicles has been a topic of interest due to their long life and high number of charge and discharge cycles. While the energy density of supercapacitors is lower than that of batteries, they can still be used to complement or combine with a storage battery or internal combustion engine to form a hybrid vehicle.

However, organic system electric double-layer supercapacitors are not practical for electric vehicles due to their high cost and low energy density. Aqueous electric double layer supercapacitor also do not meet the requirements as their energy density is lower than that of organic systems.

The electrochemical supercapacitor shows potential with higher energy density, but it introduces an electrochemical process and needs to address the battery’s shortcomings, such as poor low-temperature characteristics, short cycle life, and inability to withstand high-rate charge and discharge.

Supercapacitors can be used to absorb or release high-rate current in electric vehicles, such as in starting, acceleration, deceleration, and braking. However, their single-charge mileage is limited, and they need to be used in conjunction with other power sources.

If electrochemical supercapacitors can make breakthroughs in lifespan and power density, they may become the sole power source for electric vehicles, extending the application of supercapacitor in the automotive industry.