If you want to understand the role of capacitors in power supplies, you must understand the type of capacitors, equivalent parameters, the role of capacitors in power supply design and the role of decoupling capacitors in integrated circuit power.

1. Types of capacitors

Three commonly used capacitors: aluminum electrolytic capacitors, ceramic capacitors and tantalum capacitors.

Aluminum electrolytic capacitors: Aluminum capacitors are made of aluminum foil engraved grooves, oxidized and wound with an insulating layer, and then immersed in electrolyte solution. The principle is chemical. The capacitor charge and discharge rely on chemical reaction, and the response speed of the capacitor to the signal Restricted by the moving speed of charged ions in the electrolyte, it is generally used in low-frequency (less than 1M) filtering occasions. The ESR is mainly the sum of the aluminum resistance and the equivalent resistance of the electrolyte, and the value is relatively large.

Ceramic capacitors: The charging and discharging of ceramic chip capacitors rely on physical reactions, so they have a very high response speed and can be applied to the occasion of G.

Tantalum capacitors: Tantalum capacitors have the advantages of small size, large capacity, fast speed, low ESR, etc., and the price is relatively high.

- Equivalent parameters of capacitance

Capacitance value C: Generally, it is measured under the condition of 1kHz, 1V equivalent AC voltage, and DC bias voltage of 0V.

Capacitance Equivalent Series Inductance ESL: There is inductance in the capacitor pin. In low frequency applications, the inductance is generally small, so it can be ignored. When the frequency is higher, this inductance should be considered.

Capacitive equivalent series resistance ESR: No matter which capacitor has an equivalent series resistance, when the capacitor works at the resonance frequency, the capacitance and inductance of the capacitor are equal, so it is equivalent to a resistance, this resistance is ESR, There are great differences due to different capacitor structures. The ESR of aluminum electrolytic capacitors generally ranges from several hundred milliohms to several ohms, and the ceramic capacitors generally range from tens of milliohms. The tantalum capacitors are between aluminum electrolytic capacitors and ceramic capacitors.

- The role of capacitors in power supply design

In power supply design applications, capacitors are mainly used for filtering and decoupling / bypass.

Filtering mainly refers to filtering out external noise, and decoupling / bypass (a way to achieve the decoupling effect in the form of bypass) is to reduce the external noise interference of local circuits.

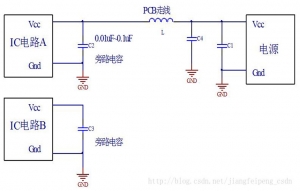

PCB trace

As shown in the figure above: The power supply (switching power supply) in the figure supplies IC chips A and B. The current passes through C1 and then passes through a PCB trace (approximately equivalent to an inductance) to separate the two paths to supply A and B respectively.

C1 filter capacitor: Because the ripple from the general switching power supply is relatively large, C1 needs to be used to filter the power supply to provide a stable voltage for A and B (C1 is equivalent to a low-frequency power supply at this time).

C2 and C3 are bypass capacitors, which play a decoupling role.

C4 decoupling capacitor: Because the bypass capacitors C2 and C3 are not ideal, sometimes high-frequency components will come out, so you need to add a decoupling capacitor to isolate interference.

- The role of decoupling capacitors in integrated circuit power supplies

The decoupling capacitor has two functions between the power supply and ground of the integrated circuit: on the one hand it is the storage capacitor of the integrated circuit, on the other hand it bypasses the high frequency noise of the device.