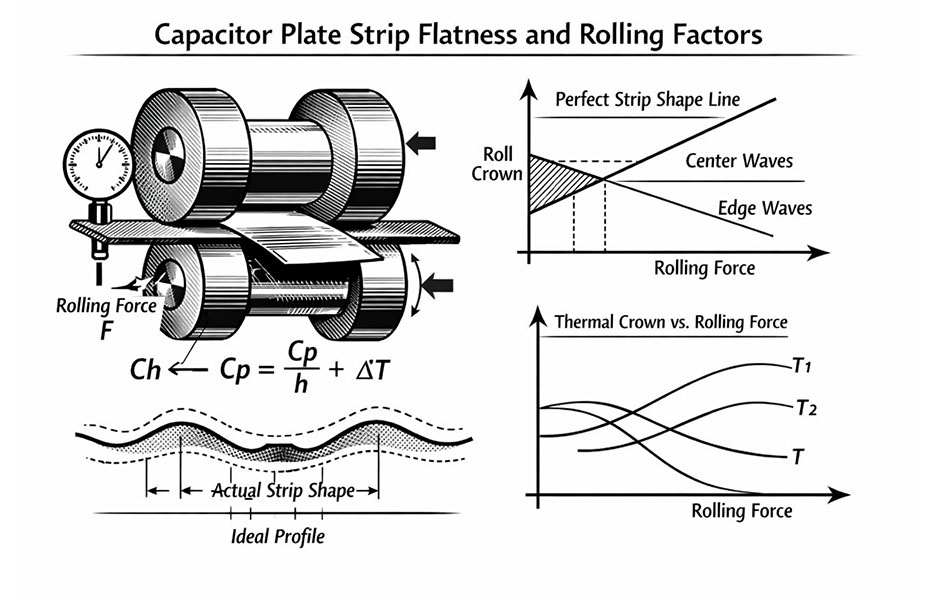

1 Electromagnetic Casting and Rolling Technology of Capacitor Aluminum Alloy

The electromagnetic casting and rolling process includes electromagnetic process parameters and casting and rolling process parameters, mainly including: excitation current, magnetic field strength, magnetic field oscillation frequency, magnetic field oscillation form, magnetic field switching frequency, which is suitable for the forming and organization control of capacitor aluminum alloy.

Excitation current: Under the premise of obtaining a sufficiently large magnetic field strength, the input excitation current should be as small as possible. This is done to save energy and prevent the electromagnetic generator coil from heating up and maintaining long-term normal operation. This requires a reasonable design of the coil of the magnetic field generator to prevent excessive inductance from causing heating losses.

Magnetic field strength: Different casting and rolling mills have different lengths of their casting and rolling zones and different widths of the casting and rolling strips, resulting in differences in the amount of melt at the crystallization front. Therefore, the requirements for the overall magnetic field are also different, that is, the number of iron core coils of the magnetic field generator is different, and the total magnetic flux generated by the electromagnetic generator is different, so as to ensure the required magnetic field strength between the casting and rolling seams. Its magnetic field strength is preferably above 500~650Gs.

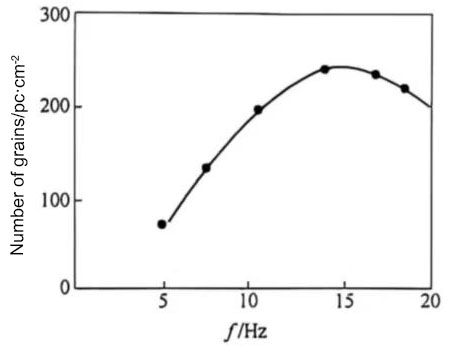

Magnetic field oscillation frequency: Oscillation frequency that is too high or too low will affect the effect of grain refinement. Experiments have shown that the electromagnetic oscillation

frequency should be in the range of 11~15Hz, and 13Hz is the optimal frequency.

Magnetic field vibration mode: After a single pulsed magnetic field reaches a certain magnetic field strength, it can refine the cast and rolled grains, but it may cause artificial grain unevenness; after adding the so-called traveling wave magnetic field, the pulsed magnetic field and the traveling wave magnetic field are combined to form a composite magnetic field to obtain an ideal, uniform, and fine equiaxed crystal structure.

Magnetic field switching frequency: The so-called magnetic field switching refers to the reversal of the traveling wave electromagnetic field running left and right along the roll gap of the casting and rolling machine to the left and right, that is, the traveling wave magnetic field changes from running from left to right to running from right to left; and vice versa. The switching frequency refers to the period or frequency of the left and right switching. The general switching frequency is 1~3 cycles to better adapt to the dynamic magnetic field requirements during the casting and rolling process of capacitor aluminum alloy.

2 Effect and analysis of electromagnetic casting and rolling

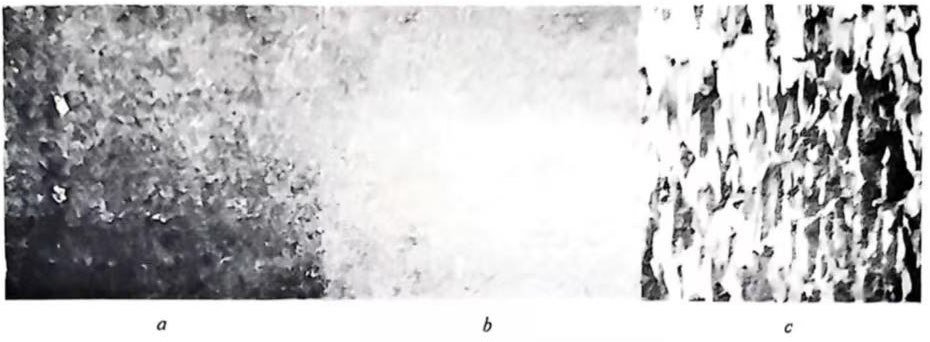

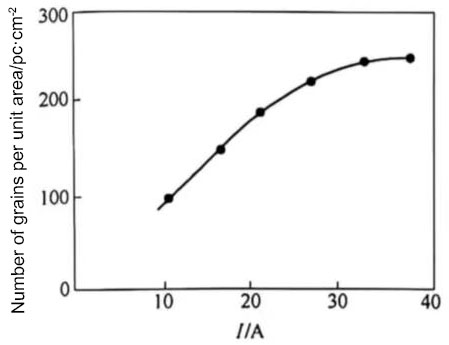

When the electromagnetic field is added to the casting and rolling crystallization front, when the magnetic field intensity reaches a certain value, no matter what kind of magnetic field is used, it can effectively refine the grains and transform the coarse grains into fine grain structures (see Figure 1). The degree of grain refinement increases with the increase of the excitation current (see Figure 2) and changes with the change of the magnetic field oscillation frequency (see Figure 3).

Figure 1 Macrostructure of the strip surface under different conditions a-electromagnetic casting and rolling sample; 6-imported aluminum titanium boron sample; c-blank sample

Figure 2 Relationship between casting and rolling grains and excitation current

Figure 3 Relationship between grain structure and electromagnetic oscillation frequency

After the electromagnetic field is applied to the casting and rolling crystallization front, the aluminum liquid oscillates due to the interactive changes and effects of the electromagnetic force, which changes the temperature field, flow field and concentration field at the crystallization front, and causes new changes in the casting and rolling crystallization mechanism. This mechanism is particularly important in the casting and rolling process of capacitor aluminum alloy, which is specifically manifested as follows:

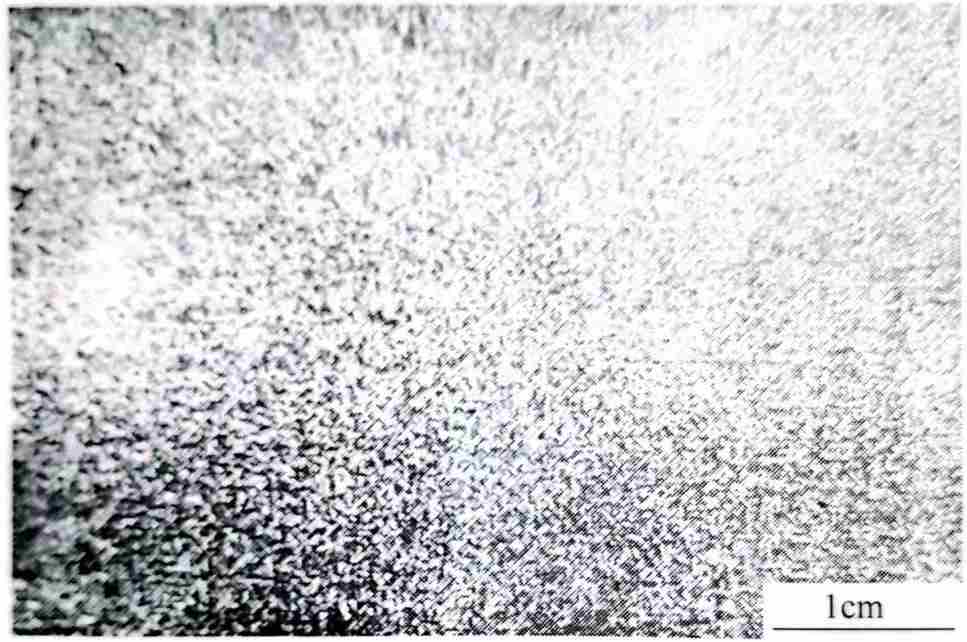

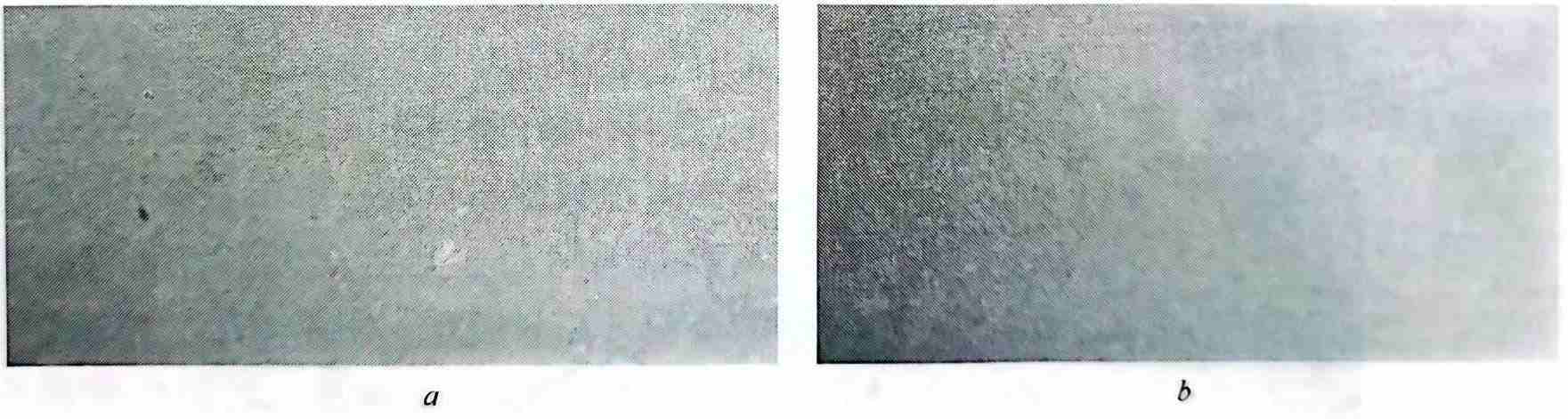

(1) Electromagnetic oscillation breaks up dendrites to become new crystallization cores. As we all know, the crystal growth at the crystallization front does not advance horizontally, but grows in a dendrite-like manner (see Figure 4). When a certain magnetic field is added to the melt, the magnetic field oscillates in a certain direction and at a certain frequency in the melt, breaking the growing front dendrites. The fragments are dispersed into the metastable fluid at the crystallization front with the stirring action of the electromagnetic field, becoming “external crystallization cores”. The metastable fluid grows into crystals based on these cores. The electromagnetic field acts very quickly, and the grain refinement effect is immediate once it is added. Figure 5 shows the macrostructure of the cast plate. The left end is the grain structure without the addition of the electromagnetic field, and the right end is the grain structure after the addition of the electromagnetic field. There is a clear dividing line between the two parts. In some electromagnetic casting and rolling samples, it can be clearly seen that the cutting line generated by the traveling wave magnetic field oscillation on the crystal to avoid solidification (see Figure 6). After the electromagnetic field passes, the dendrite is cut off.

Figure 4 Dendrite growth in the melt

Figure 5 Organization before and after adding the magnetic field a-before adding the field; 6-after adding the field (field parameters: 10Hz, 280Gs)

Figure 6 Macrostructure of cutting line when the magnetic field is weak

(2) The electromagnetic field causes uniform nucleation of the metastable fluid at the crystallization front. Several conditions are required for uniform nucleation and growth in a metastable fluid: energy fluctuations of nucleation: complex phase fluctuations of nucleation structure; and activation energy for atoms to diffuse across the solid-liquid interface. These conditions are difficult to meet in normal casting and rolling production. However, when the electromagnetic field is added, since the electromagnetic field itself is a kind of energy, and electromagnetic oscillations move sinusoidally, its energy propagation must have peaks and troughs, resulting in high-energy and low-energy regions in the metastable fluid. These high-energy and low-energy regions constantly alternate to form energy fluctuations. This energy satisfies the nucleation energy AG=16-27/3Ag required for the crystal nucleus, and provides activation energy for atoms or molecules to diffuse across the solid-liquid interface. Active energy; at the same time, electromagnetic oscillation accelerates the vibration frequency of atoms in the fluid, reduces the supercooling of the crystallization front, and is prone to complex phase fluctuations. According to formula 2-28, the nucleation rate in the melt growth will be increased, making it possible for the capacitor aluminum alloy melt to achieve uniform nucleation, grain refinement and equiaxed. Practice has shown that after the electromagnetic field is withdrawn during casting and rolling, the casting and rolling structure still presents uniform and fine equiaxed grains for a long time. This shows that in addition to the fragmented dendrite cores in the melt at the forefront of crystallization, there are already dispersed active crystal cores in the melt in the entire casting nozzle, which have a grain refinement effect.

(3) The degree of grain refinement increases with the increase of magnetic field strength. For the φ650mmx1600mm casting and rolling mill, the magnetic field strength is When the excitation current is lower than 200Cs, the effect on grain refinement is small. When the excitation current is increased, the magnetic field strength increases and the refinement effect is improved; when the magnetic field strength reaches 480Gs or above, fine primary grains can be obtained (see Figure 7). Figure 8 shows the macrostructure of electromagnetic casting and rolling and modified casting and rolling of the super casting and rolling machine. The electromagnetic casting and rolling refinement effect is completely equivalent to the aluminum titanium boron wire modification.

Figure 7 Grain structure under normal magnetic field (composite collision field, magnetic field strength: 480Gs)

Figure 8 Comparison of electromagnetic casting and rolling and modified casting and rolling a-AI-Ti-B modification; 6-electromagnetic casting and rolling (excitation current 1SA, frequency 12Hz)

(4) Grain refinement and added electromagnetic field frequency Closely related. The electromagnetic frequency in electromagnetic casting and rolling varies in the range of 0~20Hz. As shown in Figure 3, the magnetic field frequency has a better refinement effect at 10~15Hz. Below or above this frequency, the refinement effect is significantly weakened.

When the oscillation frequency is lower than 10Hz, the frequency of dendrite fragmentation is small; there are fewer areas of energy fluctuations and complex phase fluctuations in the metastable fluid; the additional oscillation frequency of atoms in the melt is low; the supercooling of the crystallization front is large, resulting in a decrease in “foreign” cores, a decrease in the spontaneous nucleation rate, and a decrease in the probability of the crystal embryo to capture atoms, thereby coarsening the cast and rolled grains. When the frequency is too low, the electromagnetic field basically loses its ability to refine the grains of capacitor aluminum alloy.

The oscillation frequency is higher than At 15Hz, the oscillation speeds up, but due to the high kinematic viscosity of aluminum melt, there is a viscous hysteresis phenomenon. The propagation of electromagnetic waves in aluminum melt will cause the medium to appear in a sparse and dense fluctuation form. In the sparse area, the medium atoms are subjected to tensile stress, and in the dense area, the medium atoms are subjected to compressive stress. For example, when subjected to tensile stress, the molten atoms move to the left, and when subjected to compressive stress, the atoms move to the right. When the oscillation frequency is too high, the atoms have not yet moved to the left under the tensile force, and then they have to move to the right under the compressive stress. In fact, there is no time to move left or right, and they can only stay still or vibrate slightly. This will neither break the dendrites at the front of the crystallization and increase the “external” crystallization cores; nor will it produce obvious energy fluctuations and complex phase fluctuations, increase the spontaneous nucleation rate, and thus reduce or lose the effect of grain refinement.

(5) Different electromagnetic oscillation modes have different effects on grain refinement. There are two basic electromagnetic fields in electromagnetic casting and rolling: the vertical pulse oscillation magnetic field; the composite oscillation magnetic field that combines the vertical oscillation with the traveling wave oscillation .

Although a single vertical pulsed magnetic field can refine the grains, the wire package and the magnetic shoes are distributed in a point-like manner along the axis of the roller, and there is a certain distance between the wire package and the magnetic shoes, so the magnetic lines of force generated by it are unevenly distributed along the axis. The magnetic line density of the points where the wire package and the magnetic shoes are located is large, and the magnetic field intensity is high; the magnetic line density of the gap area between the wire package and the magnetic shoes is small, and the magnetic field intensity is low, which leads to the generation of uneven grain bands of cast and rolled strip. The small grain band is the first-level grain, and the large grain band is the third and fourth levels.

Due to the effect of the traveling wave magnetic field, the composite oscillating magnetic field makes the magnetic field move along the axis of the roller, and the magnetic field at each point on the rolling axis is in a dynamic equilibrium state. During the entire cycle of the electromagnetic wave, its intensity is uniform, so that the capacitor aluminum alloy plate surface structure is uniform and fine, and all the grains meet the first-level standard.