1 Precautions for the operation and maintenance of filter and shunt capacitor devices

1.1 Monitoring of capacitor unbalanced current operation

🌟One of the most important functions of the AC filter and the shunt capacitor is to provide reactive power for the DC system. When the reactive power does not meet the absolute minimum filter (the absolute minimum filter capacity limit, the absolute minimum filter required to prevent the overload of the filter equipment) In any case, when this condition must be satisfied, it can lead to the occurrence of power reduction accidents in the DC system. During the operation of the DC system, operators should pay attention to the control mode of reactive power, the AC filter and the shunt capacitor input into the group When the power of the DC system changes, the switching of the filter, the backup of the filter and the parallel capacitor, etc. The above are the matters needing attention from the perspective of the AC filter and the parallel capacitor device for the safe and stable operation of the entire DC system.

✨As far as the AC and DC filter and shunt capacitor equipment itself is concerned, the operator should strengthen the monitoring of the unbalanced current of the bridge arm during the operation of the equipment. When the set value is reached, a corresponding alarm will appear in the background, but regularly pay attention to the unbalanced current situation and conduct trend analysis, which can indirectly grasp the operation of the capacitor in advance, and focus on the abnormal unbalanced current in the daily operation and maintenance. filter bank.

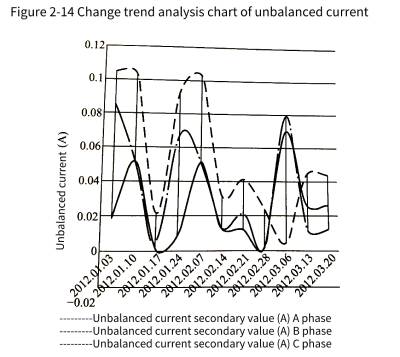

☀️The following takes a certain group of filters in the Yinchuan East converter station in the Ningdong-Shandong DC project as an example to illustrate how the operation and maintenance personnel can analyze the trend of unbalanced current: regularly copy the unbalanced current of the three phases of the capacitor (Note: Generally, regular refers to the time interval Certainly, but the analysis here mainly refers to the horizontal data comparison between the three phases. It is not particularly emphasized that the period of data copying must be constant, but the three-phase copying time should be consistent to ensure that the three phases are under the same operating conditions and environmental conditions. Comparability, because for the capacitor towers that have been precisely trimmed before being put into operation, the influence of the outside world and the system on the unbalanced current may be the main factor). As shown in Figure 2-14, the unbalanced current of the 3624 HP11/13 filter copied over a period of time is drawn with the Excel table function to draw the following trend analysis diagram. From the trend analysis chart, it can be seen that before February 28, 2012, the change trend of the unbalanced current between the three phases of the filter group was basically the same (data copied under the same operating conditions and environment). The change trends of the unbalanced currents of phases B and C are still the same, while the unbalanced current trend graph of phase A has left the “rank”, and the unbalanced current of phase A suddenly decreases greatly, indicating that the capacitance value of the capacitor bridge arm of phase A is relatively high. A large change will make the bridge arm more balanced. Conversely, the change in the capacitance value may also make the bridge hip more unbalanced. In both cases, operation and maintenance personnel should focus on strengthening monitoring.

🍎When the filter and shunt capacitor are newly put into operation or manually switched operation, attention should be paid to:

(1) When the new equipment is put into operation for the first time, it should be closed for 3 times at the rated voltage, and then open again after each closing. At least 10 minutes should be guaranteed until the next closing to ensure that the residual voltage of the capacitor discharges to within the required range.

(2) After the newly put into operation (including live debugging) about 2 hours, infrared temperature measurement should be carried out on the equipment.

(3) When the capacitor is newly put into operation for the first time (or put into operation after replacing the faulty capacitor), the unbalanced current needs to be initialized and calibrated on the protection device.

(4) The newly put into operation of the filter and shunt capacitor equipment should go to the wave recording device to print the recorded wave data when the equipment is put into operation, especially the filter and shunt capacitor with the phase selection closing device, so as to analyze whether the recorded wave data is normal or not. , and then it can be checked whether the debugged phase selection closing device is operating normally

1.2 Monitoring of the leakage current and operation of the arrester in the filter field

🍓The main purpose of monitoring the leakage current and operation of the arrester is to check whether the configuration and parameter settings of the arrester of the overvoltage protection device in the filter meet the design requirements and whether it can meet the purpose of protecting the operating equipment. Usually, the operation times and leakage current of the arrester in the filter fence are regularly recorded, and the operation of the arrester is analyzed in combination with the switching times of the filter, and the operation of the arrester can be understood from the side.

1.3 Monitoring the operation of capacitors in the filter

🍑Operation monitoring mainly refers to whether the capacitor joints are hot during operation, whether a single capacitor has bulging, oil seepage, whether there is foreign matter in the capacitor tower, etc. These are the main reasons that may cause capacitor failures.

🌼The above three items are what the operation and maintenance personnel need to pay attention to during the operation and maintenance of the equipment. The essence is the content of the daily operation and maintenance of the converter station filter equipment. The specific and detailed operation and maintenance items will be in the third section of this book. Detailed instructions in tabular form.

2 Basic requirements for the operation and maintenance of filter and shunt capacitor equipment

For the role of filters and parallel capacitors in the DC system, the following operating regulations should generally be noted:

(1) Under the normal operation of the DC system, the reactive power control mode (control of filter and parallel capacitor) is selected automatically.

(2) Under the normal operation of the DC system, the filter bank should be replaced, and the reactive power control should be switched to manual mode.

(3) Manual replacement of filters and parallel capacitors should follow the option of switching first and then cutting.

(4) When the filter and shunt capacitor are disabled, first open the circuit breaker, then open the load-side isolating switch, and then open the bus-side isolating switch. When throwing people, the sequence of operations is reversed.

(5) In the process of operation, it is found that a small amount of oil seeps through the capacitor. If it is determined by infrared temperature measurement that the capacitor has no abnormal heat, it is allowed to continue to operate. The monitoring of various state quantities of the capacitor should be strengthened (unbalanced current, infrared temperature measurement, appearance, etc.). ).

(6) Under normal circumstances, the infrared temperature measurement of the equipment should be carried out once a month, and the infrared temperature measurement should be carried out every week during the peak summer season.

(7) If abnormal discharge sound is found in the equipment during the inspection, the ultraviolet discharge test of the equipment should be carried out as soon as possible.

(8) Regularly record the operation times and leakage current of the arrester in the filter field.

(9) Regularly record and analyze the unbalanced current of the filter and parallel capacitor equipment.

(10) Carry out a nightly inspection of the equipment and equipment once a week to check whether there is any visible abnormal discharge in various equipment of the filter.