Reference News Network reported on January 10 According to Japanese media observations, insufficient semiconductor supply has led to chaos in global electric vehicle production.

According to a report by Nikkei on January 9th, semiconductors essential for automobile production are facing a growing shortage of supply. Semiconductors are indispensable components in the process of electrification of automobiles, but due to the need to meet the large demand for semiconductors in the smartphone industry, the semiconductor production industry has no stock transferred to the automotive industry. Following Volkswagen in Germany and Honda in Japan, Nissan also decided to reduce production. Toyota Motor Corporation is also unable to determine the production plan for 2021. It can be said that the impact of insufficient semiconductor supply has spread to the world.

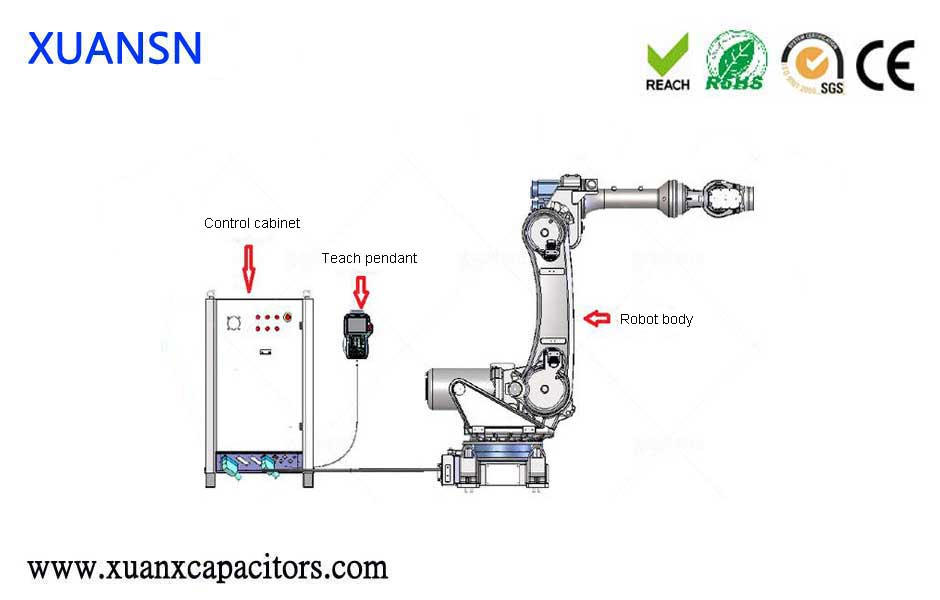

![]() The Volkswagen Group has announced that it will adjust its production in China, North America and Europe on the grounds of insufficient semiconductor supply. In Germany, the main model “Golf” will be discontinued from December 2020 to mid-January 2021. SEAT, a subsidiary of Volkswagen Group, will implement production cuts in Spain from late January to April. Honda has also decided to adjust its production plan. The production of small cars produced by Suzuka will be reduced by approximately 4,000 in January.

The Volkswagen Group has announced that it will adjust its production in China, North America and Europe on the grounds of insufficient semiconductor supply. In Germany, the main model “Golf” will be discontinued from December 2020 to mid-January 2021. SEAT, a subsidiary of Volkswagen Group, will implement production cuts in Spain from late January to April. Honda has also decided to adjust its production plan. The production of small cars produced by Suzuka will be reduced by approximately 4,000 in January.

It is reported that the main reason for the reduction in production of car companies is the delay in supply of semiconductor-attached parts by German Bosch and Continental. These semiconductors are purchased from NXP Semiconductors in the Netherlands and STMicroelectronics in Switzerland, but it seems that some semiconductors have been delayed in supply.

With the popularization of pure electric vehicles and autonomous driving technologies, the importance of automotive semiconductors has further increased. According to KPMG Japan, the average number of semiconductors used in each pure electric vehicle is twice that of a gasoline vehicle. At present, due to the sharp increase in demand after the new crown epidemic, automakers need a large amount of semiconductors. However, due to the demands of home life, semiconductor purchases for computers and smart phones are also increasing. The semiconductor industry has received a large number of orders for semiconductors of different specifications from multiple industries, which seems to be somewhat powerless.

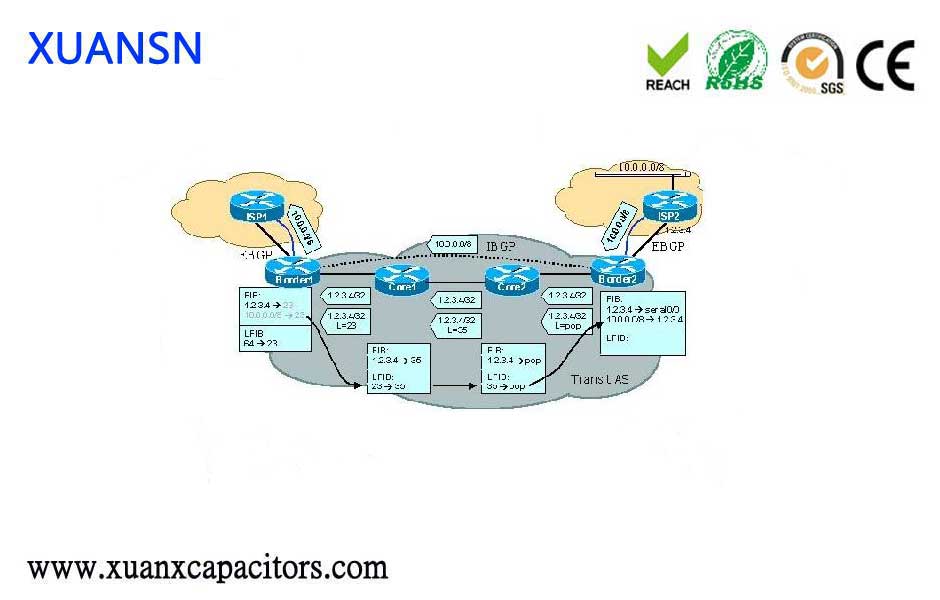

The report believes that one of the main reasons for the sluggish semiconductor supply is that the semiconductor industry is advancing the so-called “horizontal division of labor”, which means that R&D and production will be separated. Semiconductor companies often do not produce by themselves, but place orders from semiconductor foundry manufacturers. In order to produce a variety of semiconductors, it will take a certain amount of time to adjust equipment, etc., so it is difficult for foundries to manufacture different semiconductors at the same time. For some car companies to get the normal supply of semiconductors, it may take half a year later.

The report pointed out that most car production was stopped in the first half of 2020 due to the new crown epidemic. Another reason is that the automotive industry cannot compete for high-tech industries such as smart phones and mobile base stations that have expanded their business during this period. Semiconductors, which are becoming more and more important in automotive upgrades, are facing a production bottleneck, which can be said to be a new issue encountered by the industry.