How to discharge an electrolytic capacitor

1. For small lead aluminum electrolytic capacitors, just short-circuit and discharge them directly, but generally we don’t recommend them.

2. For the horn-type electrolytic capacitor with a little larger capacity, you can make a 220v/60-100w bulb, or use a resistor to discharge slowly.

3. For bolt-type high-voltage and large-capacity electrolytic capacitors, we recommend using a discharge coil, which can not only discharge the electricity of all capacitors, but is also a good helper when repairing short-circuit faults.

Remember, large electrolytic capacitors must not be directly short-circuited and discharged, otherwise the instantaneous energy is infinite, the sparks are quite dazzling, the sound is as loud as a cannonball, and life is dangerous.

Our recommendation is that all capacitors use discharge coils, which is safe, that is, it will not hurt people or equipment.

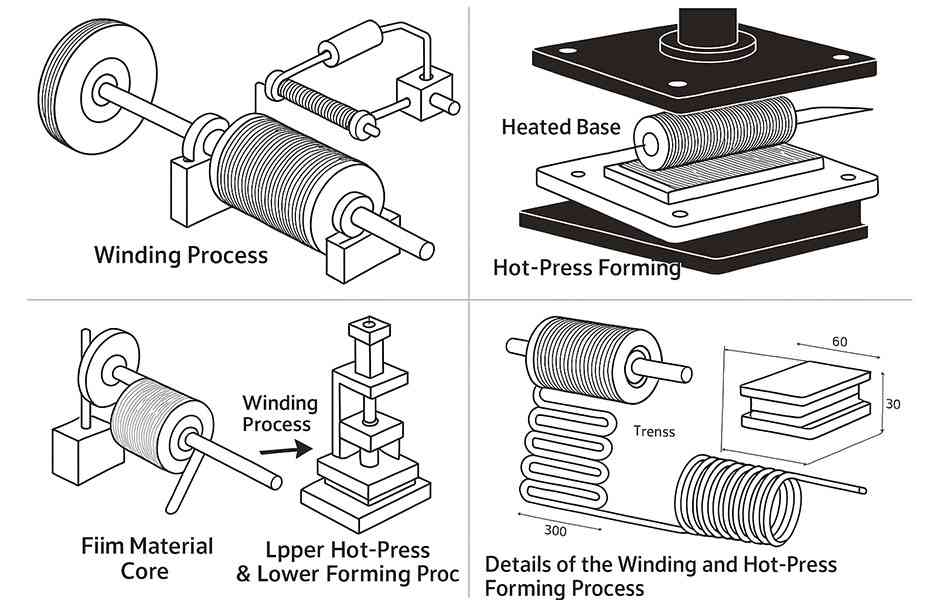

There is a very simple way. Find a short wire, about 5m or so, wind it up, use alligator clips on both ends, and connect them directly to the positive and negative poles of the capacitor to discharge. But remember one thing: one is that the wire should not be too short, and the other is that it must be wound up. Especially for high-voltage and large-capacity aluminum electrolytic capacitors, after discharging, you will find that the wires are hot.