Capacitor surface defects include:

(1) Horseshoe cracks. As a typical capacitor surface defects, horseshoe cracks are easy to appear when the casting and rolling process is abnormal. Its distribution surface is large and dense, and it may appear in groups, and sometimes even expand to the entire plate surface. The probability of a single occurrence is small. This situation may occur when the aluminum melt is overheated, stays in the furnace for a long time, the casting and rolling temperature is high, the speed is fast; the metamorphism effect is poor, the grains are coarse; the casting and rolling area is too large.

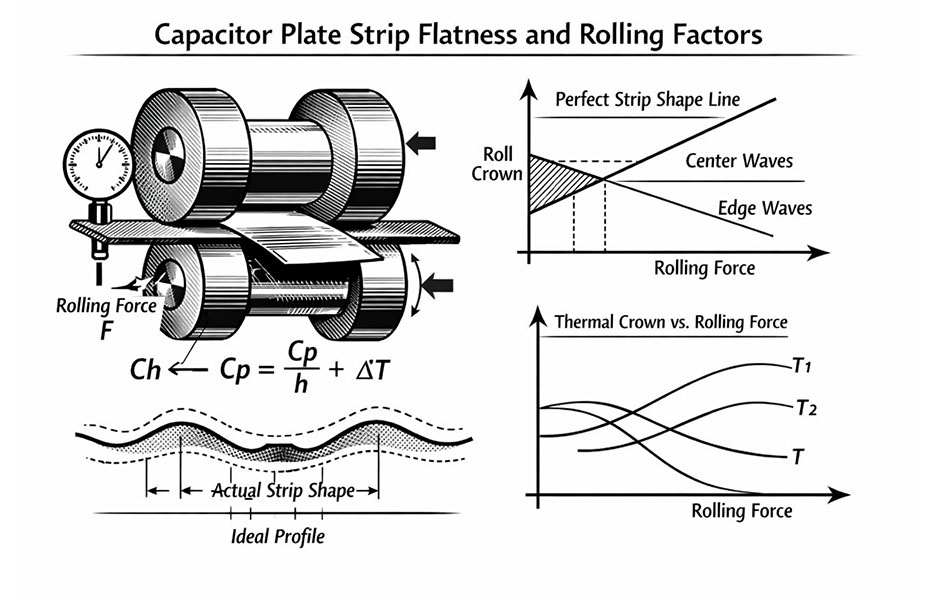

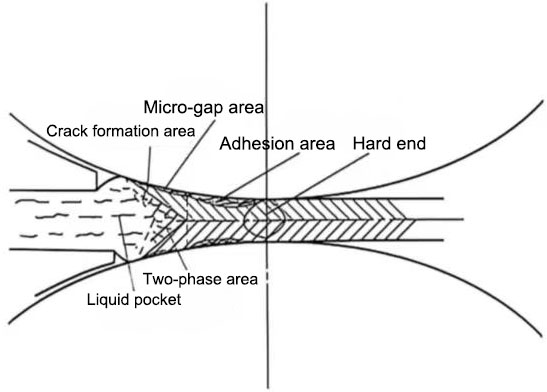

Crack formation mechanism: As mentioned above, there are three zones during casting and rolling, namely the cooling zone, the casting zone (crystallization zone), and the rolling zone. The thermal conductivity of these three zones is different. The thermal conductivity of the cooling zone is relatively high, about 3.63 J/(cm·s·K); the casting zone solidifies and shrinks due to contact with the relatively low temperature roller surface, causing the plate surface to separate from the surface, resulting in a small gap, increasing thermal resistance, and its thermal conductivity is reduced to about 0.105 J/(cm·s·K): In the rolling zone, the central metal has solidified, the metal strength has increased, and the pressure of the casting roller on the plate has increased, causing the slab to be rolled and deformed. The plate rollers are in close contact again, and its thermal conductivity is greatly increased to 20.05 J/(cm·s·K). Similar to the mechanism of the combined action of thermal stress and structural stress in the formation of capacitor surface defects, if the casting zone is increased, or the casting temperature is increased, or the casting speed is increased during the casting process, the length of the casting zone will increase, that is, the depth of the liquid cavity will increase. The casting zone has the lowest thermal conductivity, and a large amount of latent heat of crystallization is released during crystallization, which may cause some low-melting-point materials in the solidified layer to re-melt. When the rolling zone is deformed, it pulls the solidified shell of the casting zone forward together; the solidified shell is hindered by the viscosity of the liquid-solid coexistence zone, generating certain tensile stress and shear stress, so it is easy to crack. The greater the depth of the liquid cavity, the thinner the solidified shell is relatively speaking. As shown in Figure 1 and Figure 2, the depth of the liquid cavity is 0C’>0C. If the stress during metal rheology is the same, the micro-gap area is Q, but the distance from the AC’ solid-liquid interface to the micro-gap area Q is less than the distance from the AC solid-liquid interface to the micro-gap area Q (see Figure 2). Obviously, the AC solid-liquid interface is prone to cracks. Therefore, any factor that increases the depth of the liquid cavity increases the probability of horseshoe cracks.

Figure 1 Schematic diagram of the casting and rolling process

Figure 2 Schematic diagram of the analysis of the formation of horseshoe cracks

The melt residence time is long, the melt is overheated during smelting, and the metamorphic effect is poor: it will cause coarse grains. The coarser the grains, the fewer the number of grain boundaries, and grain boundaries are often concentrated areas of low-melting-point substances. In the state of fine grains, low-melting-point substances are dispersed in fine grain boundaries. As far as a single grain boundary is concerned, the concentrated low-melting-point substances are not many, and when the thermal conductivity decreases and the temperature rises, it is not enough to form cracks. However, when the grains are coarse, the number of grain boundaries decreases, the grain boundaries thicken and grow, and the low-melting-point substances are concentrated on the coarse grain boundaries. When the temperature rises, the low-melting-point substances melt, and under the action of deformation stress, cracks are formed. This cracking mechanism caused by abnormal grain structure is also similar to the formation process of capacitor surface defects, that is, microcracks or local melting phenomena are generated under the combined action of stress concentration and thermal stress.

(2) Sticking to the roll. The strip is firmly attached to the surface of the casting roll. The surface of the strip billet with sticking to the roll is dark gray, and the hardness increases, which changes the cold rolling process performance.

Causes: high casting temperature, fast speed, and low cooling intensity cause the surface temperature of the strip in the rolling zone to rise, increasing the adhesion between the strip surface and the roller surface; or the roller surface lacks lubricating substances, increasing the friction of the roller; or the presence of aluminum powder on the roller surface reduces the thermal conductivity of the roller surface, causing the plate surface temperature to rise and firmly adhere to the surface. Before the bad strip leaves the center line of the two rollers, the plate surface cannot be separated from the surface.

Solution: Use a roller cleaner to clean the roller surface; use methods such as spraying graphite solution or flame spraying to lubricate the roller, reducing the casting temperature, reducing the casting speed, and appropriately increasing the traction to prevent sticking to the roller.

(3) Water ripples. There are strips of ripples on the surface of the strip (see Figure 3), and the distance between the lines is generally about 2~3mm. Sometimes it appears on the entire plate surface, and sometimes only on the edge of the bad strip. The probability of appearing on the lower surface is greater than that on the upper surface. The larger the alloy crystallization range, the more obvious the water ripples. The crystallization range of 5052 alloy is 40℃, and its water ripples are significantly more serious than pure aluminum (see Figure 4). Similar corrugated surface abnormalities may also appear as non-uniform expansion or surface undulations in capacitor surface defects, affecting the subsequent performance and appearance quality of the device.

Figure 3 Water ripples on the surface of 1050 alloy strip

a-lower surface, obvious water ripples; b-upper surface, no water ripples

Figure 4 Water ripples on the surface of 5052 alloy strip

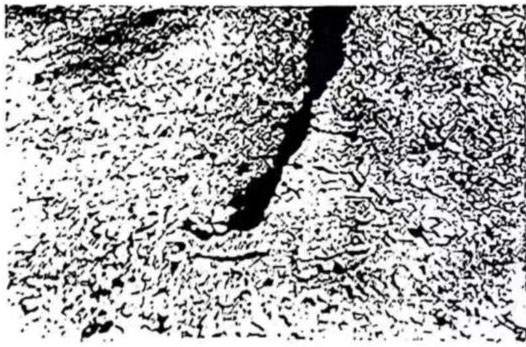

The impact of water ripples on product quality: When the total cold working rate is small and the water ripples are more serious, traces of ripples will be left on the board surface, affecting the appearance of the board surface. The organization after alkali washing is shown in Figures 5 and 6. The production of PS plates with higher surface quality requirements may affect the roughness uniformity of the board and leave spots on the board surface. When the total processing rate of the plate reaches a certain level, no traces of water ripples can be seen.

Figure 5 Surface structure of 1050 alloy after annealing after rolling from 7.0mm to 3.0mm (top, lower surface of cast-rolled plate)

Figure 6 Surface structure of 1050 alloy after annealing after rolling from 7.0mm to 3.0mm (top, upper surface of rolled plate)

The formation of water ripples is related to the equipment condition, alloy nature, and casting and rolling process.

Resonance produces water ripples. Any equipment has an inherent vibration frequency. During casting and rolling production, when the vibration frequency occurring at a certain casting and rolling speed is the same or similar to the inherent vibration frequency of the equipment, resonance will occur, which will intensify the vibration; the meniscus of the melt at the gap between the nozzle rollers at the pseudo-rolling front edge will fluctuate with the resonance frequency, and the thickness of the oxide film at the meniscus will change accordingly, leaving strips of water ripples on the surface of the cast-rolled plate. This periodic surface fluctuation caused by mechanical vibration is essentially similar to the formation mechanism of some capacitor surface defects, especially the surface film disturbance phenomenon that is prone to occur under heat treatment or impact vibration conditions. When the resonance is serious, the fluctuation may be large, which may cause the oxide film of the latter fluctuation to cover the oxide film of the previous fluctuation, forming the so-called oxide film fold (see Figure 7). By changing the casting speed, resonance is avoided to eliminate water ripples.

Figure 7 Casting and rolling of pure aluminum strip due to resonance

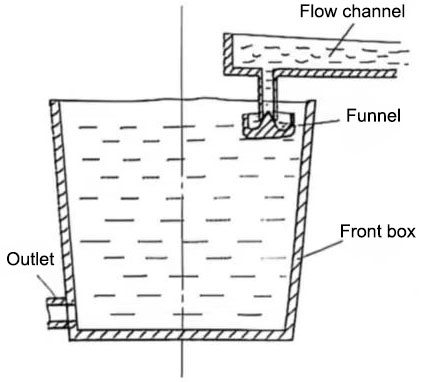

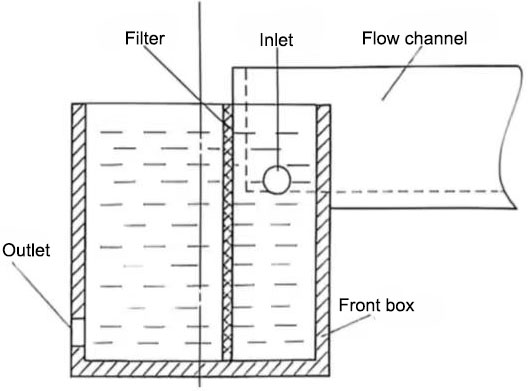

The liquid level of the front box fluctuates, and the diffraction of the wave will cause the oxide film folding formed by water waves. The aluminum liquid enters the front box through the flow trough from the filter box. There are generally two ways to enter the front box: 1) The bottom of the flow trough is higher than the top of the front box, and the aluminum liquid is injected from the top of the front box (see Figure 8). In this case, the liquid level of the front box is controlled to be stable, and the liquid level will not fluctuate up and down. 2) The bottom of the flow trough is lower than the top of the front box, and the liquid flow is injected from the middle and upper part of the side of the front box (see Figure 9).

Figure 8 Injected from the top of the box

Figure 9 Aluminum liquid is injected from the middle and upper part of the side of the front box

Due to the large drop between the liquid level of the flow trough and the injection site of the aluminum liquid, the inlet generally uses a brazing rod to control the liquid flow. When the drill bit is close to the lower part of the flow orifice, the aluminum liquid is injected from the gap between the upper part of the flow orifice and the drill bit, which often forms waves on the liquid surface, causing the liquid surface to fluctuate, thereby causing the meniscus at the gap between the nozzle roller to fluctuate, resulting in water ripples on the surface of the cast-rolled strip. If the drill bit is close to the upper part of the flow orifice, the aluminum liquid is injected from the gap between the lower part of the flow orifice and the drill bit. At this time, the liquid surface of the front box is basically stable, but there are still fluctuations below the stable surface. This wave diffracts through the outlet and transmits the wave to the gap between the nozzle roller, causing the meniscus to fluctuate, causing the strip to produce water ripples. To reduce or eliminate this water ripple, it is necessary to prevent the fluctuations generated by the unstable injection of aluminum liquid at the inlet from being transmitted to the casting front. Therefore, a vertical filter can be added between the inlet and the outlet of the front box to prevent the propagation and diffraction of the wave, which can reduce or eliminate the water ripples. If the liquid surface area between the filter and the outlet is appropriately increased, the effect will be more obvious.

In addition, other measures can be taken in the process, such as minimizing or eliminating the gap between the nozzle rollers to reduce or eliminate water ripples. However, when the gap between the nozzle rollers is reduced to a certain extent, defects such as roller marks and surface segregation may appear on the surface of the strip. These defects can also be compared to a form of capacitor surface defects in metal products. Reducing the casting temperature or the casting speed, increasing the surface tension of the aluminum oxide film on the meniscus at the gap between the nozzle rollers, increasing the radius of curvature of the meniscus, and reducing the fluctuation of the meniscus can reduce or eliminate water ripples. However, doing so will significantly reduce production efficiency and easily cause damage to the casting nozzle and stop casting.

Problems in the manufacturing and installation quality of casting and rolling equipment can also cause water ripples. The casting and rolling machine has low gear matching accuracy, which produces gap-type impact when rotating; the installation is not tightened and becomes loose, causing the aluminum liquid in the nozzle gap to fluctuate during operation, leaving water ripples on the plate surface.

(4) Tropical zone. Part of the aluminum melt is pulled out of the casting and rolling zone before crystallization is completed, leaving a cast strip structure on the plate surface that has not been rolled and deformed. The reason is that the liquid level of the front box is low, the static pressure of the aluminum liquid is insufficient, and the aluminum melt in the casting nozzle is not completely filled, resulting in gaps in some roll gaps during casting and rolling due to the metal not being filled, and the melt failing to contact the upper casting roll, which reduces the cooling intensity here, and the melt cannot complete the crystallization process before leaving the casting roll gap. Or the temperature in the casting nozzle is low, causing large-area blockage, and the aluminum liquid cannot be replenished smoothly.

Solution: Increase the liquid level of the front box and reduce the casting speed; or appropriately increase the casting temperature to increase the fluidity of the aluminum melt in the casting nozzle.

(5) Cracking. The casting roll has been used for too long. Due to the effects of thermal stress, mechanical stress, phase change stress and the erosion of the aluminum melt on the roll sleeve surface (this issue will be discussed in the following chapters), a network of cracks like a tortoise shell appears on the rolling surface. When the strip passes through the rolling zone, it is copied to the strip surface, forming tortoise cracks. The tortoise cracks will affect the surface quality of the plate, strip and foil, especially for high-quality foil, it will increase the pinhole rate and even cause the strip to break, affecting normal rolling. For the PS aluminum plate base, it affects the uniformity of its surface roughness and may increase its black and white stripe defects after electrolysis, which is equivalent to the “cracking type” in the classification of capacitor surface defects.

(6) Triangular mouth or hole. When the plate is erected, the ambient temperature is high and the humidity is high, while the casting and rolling surface temperature is low. Water vapor condenses on the surface and immediately vaporizes when it encounters high-temperature aluminum melt, forming holes. Sometimes, a clear liquid water film can be observed on the surface corresponding to the hole.

Extending the preheating time or slag running time of the roll and increasing the roll surface temperature of the roll can prevent water vapor from condensing on the roll surface.

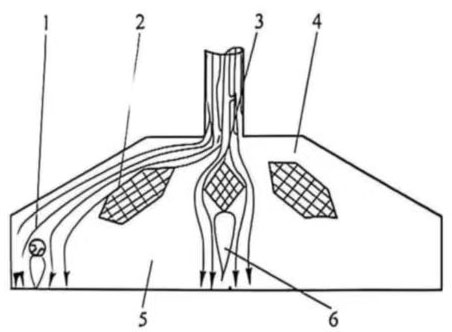

(7) Slot grooves, slot airways, and slot cracks. Casting and rolling is a continuous production method. Replacing a pair of casting nozzles requires the production of dozens, hundreds, or even thousands of tons of products. The aluminum melt continuously flows through the casting nozzle, and at the same time, a part of the inclusions in the melt are precipitated in the nozzle cavity. As the production time increases, more and more sediments are left in the mouth cavity and lips, and most of these sediments are aluminum, titanium, and boron oxides. In places where there are more compound precipitations, small pyramid-shaped peaks are formed (see Figure 10), which hinder the flow of aluminum liquid and change the streamlines of the fluid. These precipitated slags are not infiltrated by aluminum liquid, and they are easy to become bubble cores below the fluid. The hydrogen dissolved in the aluminum liquid will diffuse into them after precipitation, causing the bubbles to gradually grow and be elongated into gas cones (see Figure 11). When the gas cone enters the casting and rolling area, an air channel is formed in the strip. If the gas cone fails to form below the precipitate, when the melt passes through the slag peak, a small groove is drawn on the surface of the melt, and the oxide film on the surface is destroyed, causing the crystal orientation of the grains on both sides of the peak to change, which may form defects such as wire cracks and cold shuts (see Figures 12 and 13). This type of structural change process and defect evolution can also be compared with the microscopic heterogeneous structural process of capacitor surface defects.

Figure 10 There is a protruding peak-shaped oxide at the front end of the casting nozzle lip

Figure 11 Schematic diagram of gas cone formation 1-melt flow line; 2~4-block; 5-strip 6-bubble is elongated into a gas cone

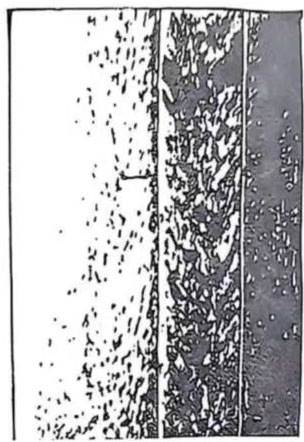

Figure 12 Crystalline structure on both sides of the groove of the strip

Figure 13 Cross-section of the groove of the pass rod (microstructure)

(8) Surface segregation. If the gap between the casting nozzle and the roller is too small, alumina powder, graphite powder (when graphite spraying or flame spraying is used), etc. may accumulate in certain parts of the gap. As the casting roller rotates, the dust adhering to the casting lip may be transferred to the surface of the casting roller. When the roller surface with dust adhering to it enters the casting zone, the aluminum liquid contacts the powder layer. The thermal conductivity of the powder layer is much lower than that of the roller, causing the aluminum liquid passing through this part to crystallize later, and the crystal orientation and grain size are changed, forming surface segregation, which will affect the organizational properties and surface quality of the product. If the powder layer forms a long strip on the surface of the roller, a segregation band will be generated on the plate (see Figure 14); if the powder layer only forms a plaque, a patchy segregation area will be formed on the slab. If the melt forms a vortex at the front of the casting nozzle (see Figure 15), the flow line of the melt is changed, and the cast plate structure may also produce a vortex-type segregation. This segregation phenomenon has a representative non-uniform distribution feature and can be used as a reference sample for studying the distribution pattern of capacitor surface defects.

Figure 14 Segregation band on the surface of the cast plate

Figure 15 Melt vortex formed at the front of the casting nozzle

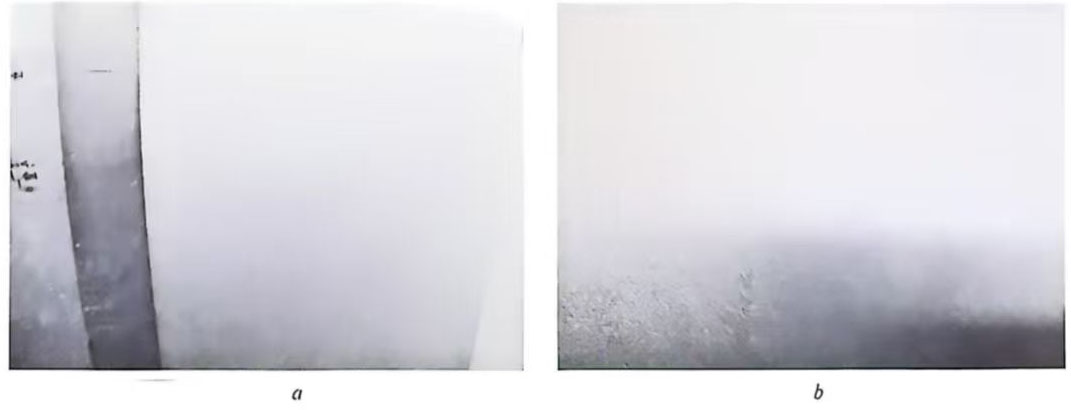

(9) Roller marks, light and dark stripes. There are defects in the grinding of the casting roller or guide roller, such as grinding spiral lines, vibration lines, etc. Figure 16a shows the spiral lines parallel to each other on the surface of the strip caused by the casting roller marks or guide roller marks. When the casting nozzle is assembled, the roller gap is too small, and the casting roller is eccentric; or during the casting process, hard phase particles are sandwiched between the nozzle roller gap, causing the casting or hard phase particles to rub against the roller surface, thereby producing light and dark stripes on the plate surface with a large contrast with the base surface (see Figure 16b). These stripes will have a serious adverse effect on the production of PS aluminum plate base and high-end decorative strips, which is highly similar to the macroscopic surface abnormalities such as stripes and scratches in capacitor surface defects.

Figure 16 Spiral stripes () and dark stripes (b) on the rolled strip