1.Metal Deformation in Capacitor Cold Rolling Deformation

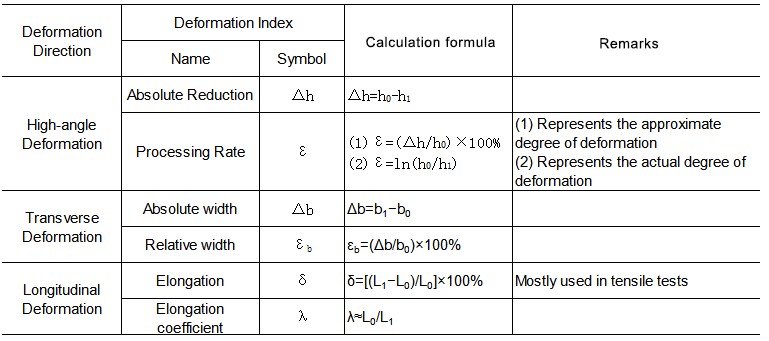

During rolling, metal undergoes plastic deformation under external force, resulting in dimensional changes in the height, width, and length of the rolled piece. These dimensional changes are also significant during the capacitor cold rolling deformation. The magnitude of this deformation is called the deformation index. Commonly used deformation indices are shown in Table 1. In the table, h0, b0, L0 represent the height, width, and length of the rolled piece before rolling, respectively; h1, b1, L1 represent the height, width, and length of the rolled piece after rolling, respectively.

Table 1 Commonly Used Deformation Indices

2.Determination of Rolling Regime

Before determining the rolling regime, the requirements for the finished product’s dimensions, processing state, surface quality, microstructure, and mechanical properties should be considered. Different processing regimes are adopted for different requirements. XUANSN will develop corresponding process plans based on actual conditions during production.

2.1 Cold Working Rate for PS Plate Aluminum Base and Foil Raw Materials

The cold working rate is determined according to user requirements.

For PS plate aluminum substrates requiring good uniformity of grain size, moderate mechanical properties, and moderate hardness after electrolysis, high-temperature annealing can be performed after one pass of cold rolling. This eliminates non-equilibrium crystallization structures occurring during casting and rolling, homogenizes the alloy composition, improves processability, and enhances surface quality. If high strength and high hardness are required to improve the printing durability of the PS plate, intermediate annealing is unnecessary, and it can be directly cold-rolled to the finished product.

For aluminum foil raw materials, the degree of deformation before annealing or between two annealing cycles is determined based on the thickness of the finished aluminum foil.

There is a certain relationship between the degree of metal deformation, the annealing temperature after deformation, and the size of the recrystallized grains. This relationship is also very important in the capacitor cold rolling deformation process. A small metal deformation rate and a high annealing temperature result in fewer recrystallization nuclei, leading to coarse recrystallized grains (this issue will be discussed in detail in the annealing heat treatment section). This deformation rate is called the critical deformation rate. Except in special cases, the total processing rate of the metal must be greater than the critical processing rate. However, for some materials, an excessively high total processing ratio (generally greater than 85%) can easily lead to secondary grain growth during annealing, resulting in uneven, coarse grains appearing on a fine-grained substrate. For these materials, the total processing ratio before intermediate annealing is generally controlled below 80%, or the annealing temperature and holding time are strictly controlled during finished product annealing to prevent secondary recrystallization and grain growth.

2.2 Production Requirements for Low Earing Ratio in Deep-Drawing Sheet and Strip

For products with specific requirements for microstructure, such as deep-drawing sheet and strip requiring a low earing ratio, the cold working ratio after annealing should be controlled during process design.

Under normal circumstances, the orientation of grains is randomly distributed, and mechanical properties are isotropic. During cold rolling, when a certain degree of deformation is reached, the lattice orientation within the grains rotates, causing specific crystal planes and orientations to align in a certain direction. This orders the originally disordered grains, resulting in a more strictly oriented relationship, i.e., forming the so-called deformation texture.

The presence of fibrous structure and deformation texture leads to anisotropy in materials, meaning that mechanical properties differ in directions at 0°, 45°, and 90° to the rolling direction.

Deformation texture becomes more pronounced with increasing deformation. Typically, a clear orientation and deformation texture only become apparent after the total cold rolling processing rate reaches 50%–60%.

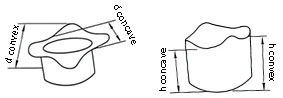

This texture is detrimental to subsequent forming processes such as deep drawing and deep drawing. Similar problems arise during deep drawing of materials related to capacitor cold rolling deformation: some directions extend more, forming bulges, while others extend less, forming depressions, and even cracking. The bulges or depressions are symmetrically distributed, forming what is called “ears,” as shown in Figure 1. The bulges may form angles of 0°, 90°, and 45° to the rolling direction, commonly referred to as 0°, 90°, and 45° ears, respectively.

Figure 1. Earing pattern of deep-drawn parts

The size of the ear is expressed by the earing rate:

![]() (1)

(1)

![]() (2)

(2)

Where h1 − height of the raised portion;

h2 − height of the recessed portion;

d1 − diameter of the raised portion;

d2 − diameter of the recessed portion.

For pure aluminum with a total cold rolling processing rate of 90%, the deep-drawing earing rate is 5%–6%, with 45° earing appearing. If an intermediate annealing is added during processing, the deep-drawing earing rate can be reduced to 1%–3%. To reduce the earing rate, the total cold rolling processing rate should not be too high, preferably controlled at around 50%. However, for certain cold-work-strengthened materials with special requirements, the tensile strength needs to be met in an extra-hard state (total cold rolling processing rate above 90%), while simultaneously requiring a very low lug rate. This necessitates reasonable process measures, such as adjusting the alloy’s chemical composition, researching pre-cold rolling hot working processes, and developing new cold rolling methods to improve the deformation texture during metal cold rolling and achieve lugs in the 0°, 90°, and 45° directions.

2.3 Determination of Pass Processing Rate and Total Processing Rate

During cold rolling, the rolled piece undergoes work hardening, increasing yield strength and decreasing plasticity. This phenomenon also exists in the processing of capacitor cold rolling deformation. When the degree of cold deformation reaches 45%~55%, the elongation of pure aluminum and almost all aluminum alloys is roughly the same, approximately 3%~5%. However, their ability to continue cold rolling differs. Some alloys may not develop edge cracks during subsequent cold rolling, resulting in smooth deformation and a total cold rolling yield exceeding 90%, and even exceeding 95% when rolling soft aluminum alloys. However, other alloys will develop edge cracks during continued cold rolling without intermediate annealing, increasing the difficulty of deformation. Therefore, the elongation of an alloy cannot be used as the basis for determining the rolling process, but the amount of deformation at which edge cracks occur can be used as a standard for determining the processing technology.

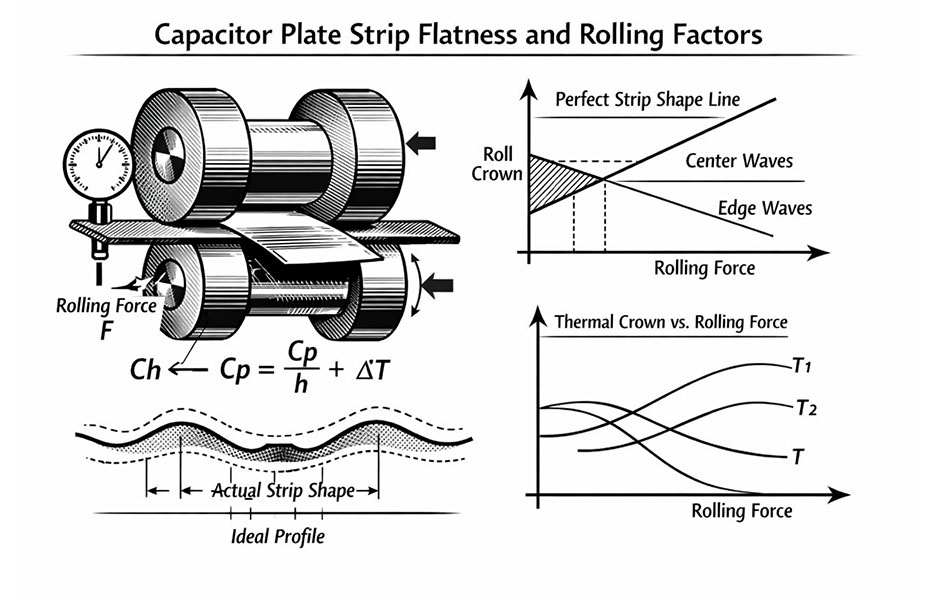

The pass rate. In the capacitor cold rolling deformation process, within the plastic range of the alloy, and while achieving good surface quality and rolling quality, a larger pass rate should be used as much as possible to reduce the number of rolling passes and improve production efficiency. However, the pass rate must consider equipment conditions, mainly limited by the maximum rolling force; it must also consider mill performance, process lubrication and cooling conditions, the magnitude of the absolute reduction, the original roll profile and operating level, and the characteristics of the alloy. In the cold rolling stage, the pass reduction rate for soft alloys is generally between 30% and 60%; however, for some alloys with severe hardening and edge cracking, the pass reduction rate may only be 10% to 20%.

For some alloys, intermediate annealing is required after a certain total deformation to prevent edge cracking during cold rolling. For some aluminum alloys, even annealed products must reach a certain total deformation; otherwise, the final mechanical properties cannot be guaranteed. For example, with 5A06 alloy, when the total deformation is below 50%, the yield strength is difficult to meet the technical standard requirements.

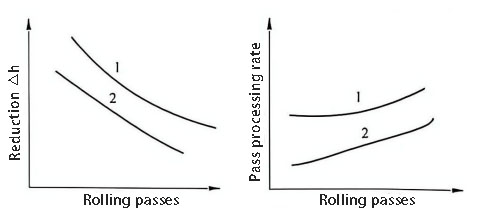

During production, XUANSN adjusts the rolling regime according to actual conditions. The pass reduction or pass processing rate curve should ideally maintain a smooth decline or smooth rise, and its trend is shown in Figure 2.

Figure 2 Trend of Pass Reduction and Processing Rate Distribution during Cold Rolling

1-Pure Aluminum, Soft Alloy; 2-Hard Aluminum Alloy