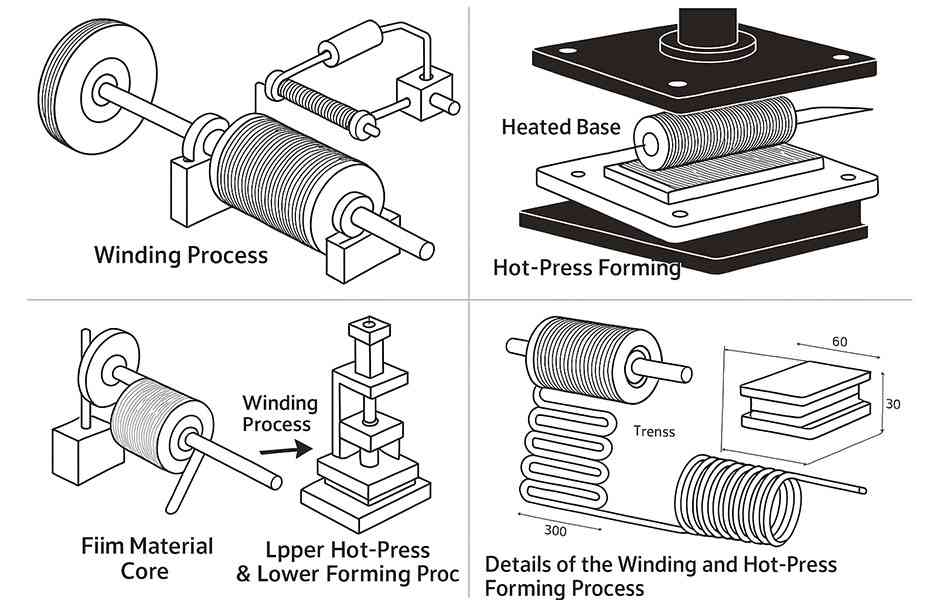

1.Determination of Rolling Speedand Capacitor Material Control

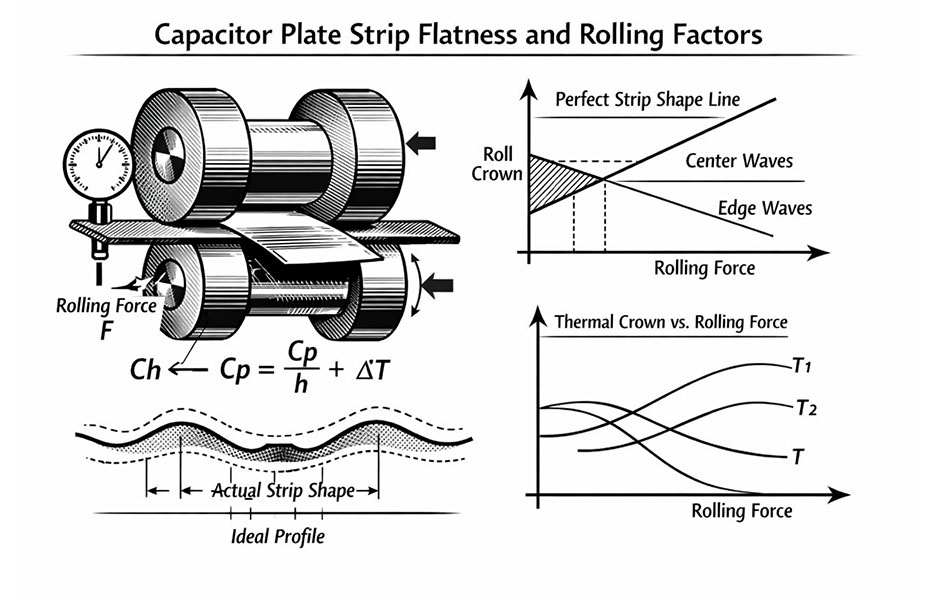

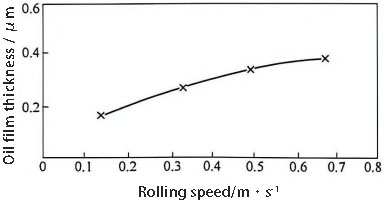

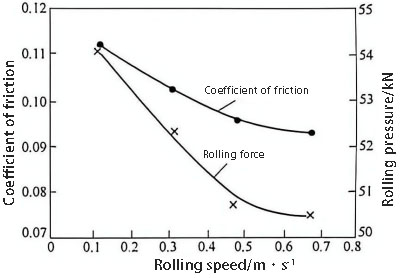

With the development of rolling technology, rolling speeds are becoming increasingly faster. In the capacitor material control process, as the rolling speed increases, the oil film thickness increases due to the oil wedge effect (see Figure 1), while the rolling force and friction coefficient decrease (see Figure 2). Therefore, high-speed rolling can not only improve production efficiency but also save energy and improve product quality.

Figure 1 Relationship between Rolling Speed and Oil Film Thickness

Figure 2 Relationship between Rolling Speed, Rolling Force, and Friction Coefficient

From the perspective of equipment performance indicators, high-speed rolling mills operating at a speed of 800 m/min best utilize the performance and level of the XUANSN equipment’s automatic control system for thickness and shape.

In actual operation, there is no standard fixed value for the appropriate rolling speed for capacitor material control; it needs to be determined based on the actual situation. Generally, the initial rolling pass has a lower speed, while the final rolling pass has a higher speed; the absolute reduction is large, so the speed is lower, and the absolute reduction is small, so the speed is higher; for products delivered in a hard state and requiring good mechanical properties, the finishing pass should use high-speed rolling to achieve dynamic recovery and improve the elongation of the material.

High-speed rolling has obvious advantages, but it is not suitable for all conditions. The following conditions should be met for high-speed rolling:

(1) It has an automatically controlled and effective cooling system. During high-speed rolling, it must effectively reduce the temperature of the rolls and the rolled piece to prevent excessive roll temperature and aluminum sticking.

(2) The properties of the lubricant must meet the requirements of high-speed rolling.

(3) High-speed rolling has corresponding automatic thickness control and automatic shape control systems. Simultaneously, during acceleration and deceleration at the beginning and end of rolling, it should automatically adjust the roll gap accordingly to ensure that the longitudinal thickness deviation meets the standard requirements.

(4) It has an automatic strip breakage and shutdown protection system, which can accurately and quickly stop the equipment in case of failure.

2.Lubricant Selection and Temperature Control

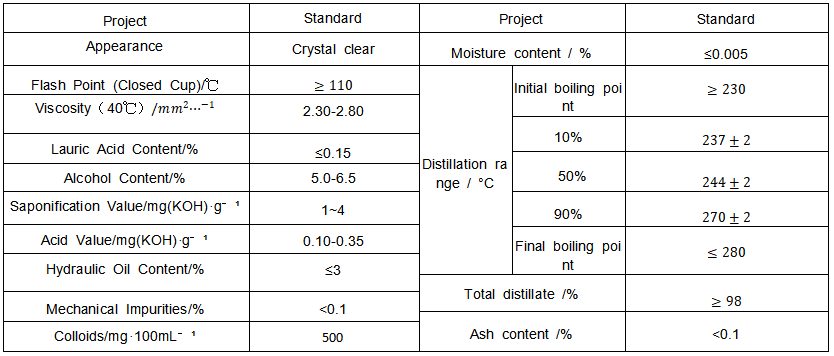

In the cold rolling of aluminum and aluminum alloys, to achieve control over capacitor materials, XUANSN uses lubricants composed of base oil and certain additives. The base oil is generally a mineral oil containing C-H chains, with 5%~7% composite additives added. The physicochemical properties of the rolling lubricant after adding additives should meet the technical requirements. Reference values for the physicochemical properties of cold rolling lubricants for producing soft alloy series are shown in Table 1.

Table 1 Reference Values for Physicochemical Properties of Cold Rolling Lubricants

The kinematic viscosity of cold rolling lubricants changes with temperature. At lower temperatures, the viscosity is higher, resulting in better compressive strength and the ability to withstand greater rolling forces, increasing the reduction. However, this increases the amount of oil carried on the strip, resulting in a thicker oil film and affecting the surface quality of the strip. At higher temperatures, the viscosity is lower, resulting in lower compressive strength, easier oil film rupture, and a tendency for the strip to develop dendritic patterns. Generally, the operating temperature of the lubricant is controlled between 35~50℃.

3.Tension Control During Strip Rolling for Capacitor Material Control

Modern strip rolling mills are equipped with robust front and rear tension systems to meet the requirements of capacitor material control. The front tension can exceed the yield strength of the smallest locally elongated portion of the strip, thus preventing uneven metal elongation and waviness, resulting in a strip with better surface flatness and a better shape.

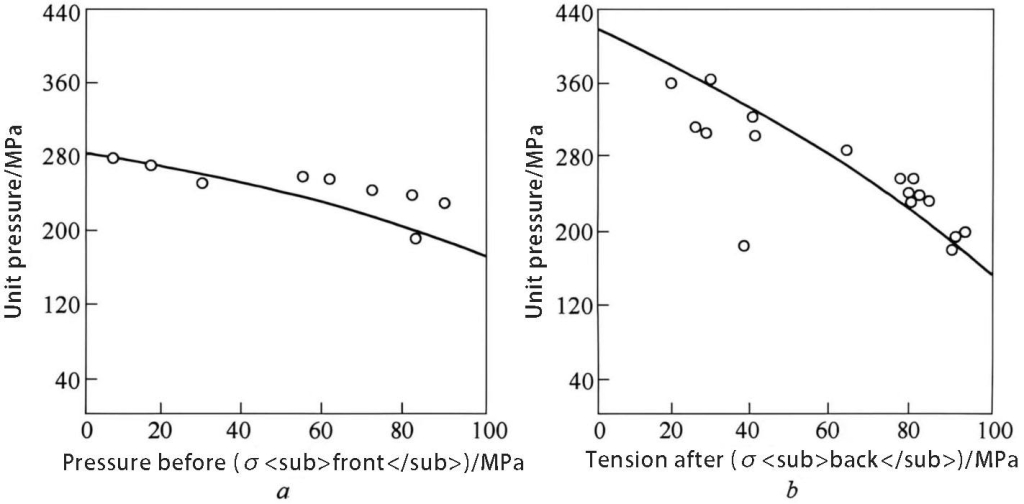

Increasing tension reduces rolling force. As shown in Figure 3, the reduction in rolling force caused by increasing rear tension is more significant than that caused by front tension. However, improper tension control, especially when using polishing rolls, can lead to excessive back slip, reducing or even eliminating the front slip value. This causes the strip to “slip” on the rolls, making it difficult to establish a stable rolling process. In such cases, the rear tension should be appropriately reduced while the front tension is increased.

Figure 3. Relationship between front and rear tension and unit pressure (pure aluminum)

a-Front tension (![]() ); b-Rear tension (

); b-Rear tension (![]() )

)

Tension improves the alignment of the strip during rolling, preventing or reducing strip deviation when tension is not applied, thus creating favorable conditions for high-speed rolling. However, under capacitor material control, tension rolling requires appropriate adjustment based on specific circumstances; otherwise, it will cause strip breakage or interlayer misalignment, resulting in strip delamination and surface scratches.

The maximum tension used in cold rolling should theoretically not exceed the yield strength σ0.20 of the rolled material. When rolling aluminum alloy strips, depending on the material’s plasticity and edge condition, a unit tension value of 5% to 60% of the yield strength of the strip in that pass is generally used. On 2800mm and 1700mm quadruple cold rolling mills, the pre- and post-tension values (MPa) of cold-rolled aluminum alloy strip can be calculated using the following empirical formulas, depending on the thickness of the rolled piece:

Pre-tension σBefore = 56.7 − 6hAfter

Post-tension σAfter = 43 − 5hBefore

Where hBefore and hAfter are the thicknesses before and after rolling, respectively, in mm.

The tension adjustment range (the ratio of maximum to minimum tension) is generally 10:1 to 20:1. Within this range, the given tension value can be accurately achieved. The tension on the strip during rolling should be kept as stable and constant as possible, especially during stable rolling processes. Fluctuations in tension can cause minor issues such as misalignment between coil layers, resulting in surface scratches on the strip; severe fluctuations can even cause the strip to break. The tension fluctuation range is generally specified as ±1%~3%.

During the rolling process, to achieve control of the capacitor material, the work hardening degree of the strip increases with the increase of rolling passes, i.e., the yield strength of the rolled piece increases accordingly. Therefore, the selected unit tension value for each pass must also increase accordingly. The uncoiling tension on a coiler should be less than the coiling tension of the previous pass to avoid slippage between coil layers during uncoiling, which could scratch the strip surface.

4.Examples of Cold Rolling Production Processes (Reference)

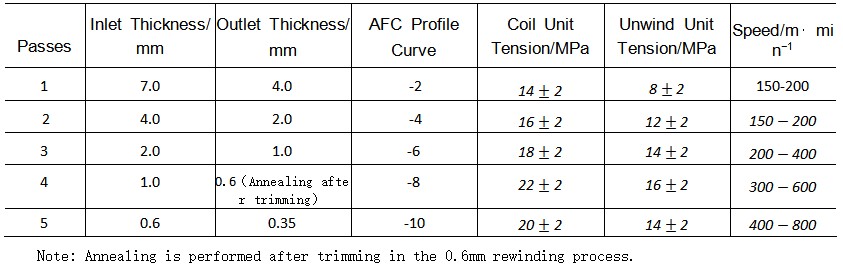

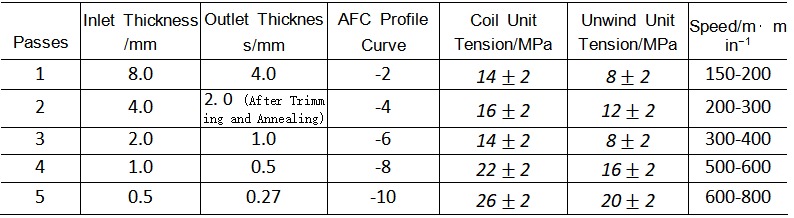

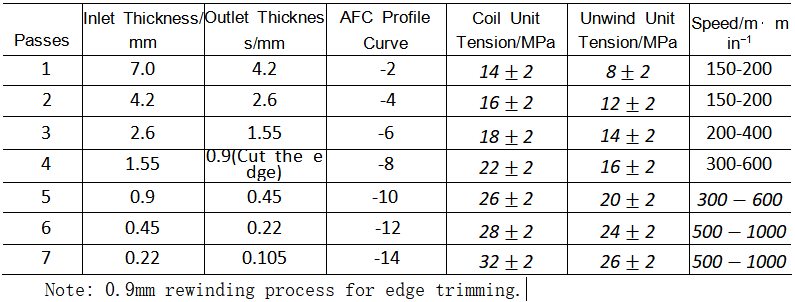

Examples of some products and alloys in the cold rolling production process are shown in Tables 2 to 5.

Table 2 Reference Values for Cold Rolling Process of PS Plate Base (1050 Alloy, 1060 Alloy; Width: 800-1200mm)

Table 3 Reference Values for Cold Rolling Process of Air Conditioning Foil (3102 Alloy, 8011 Alloy; Width: 1300~1700mm)

Table 4 Reference Values for Cold Rolling Process of Decorative Strip (1100 Alloy; Width: 1290~1610mm)

Table 5 Reference Values for Cold Rolling Process of Double-Zero Foil Raw Material (1235 Alloy; Width: 1300~1700mm)