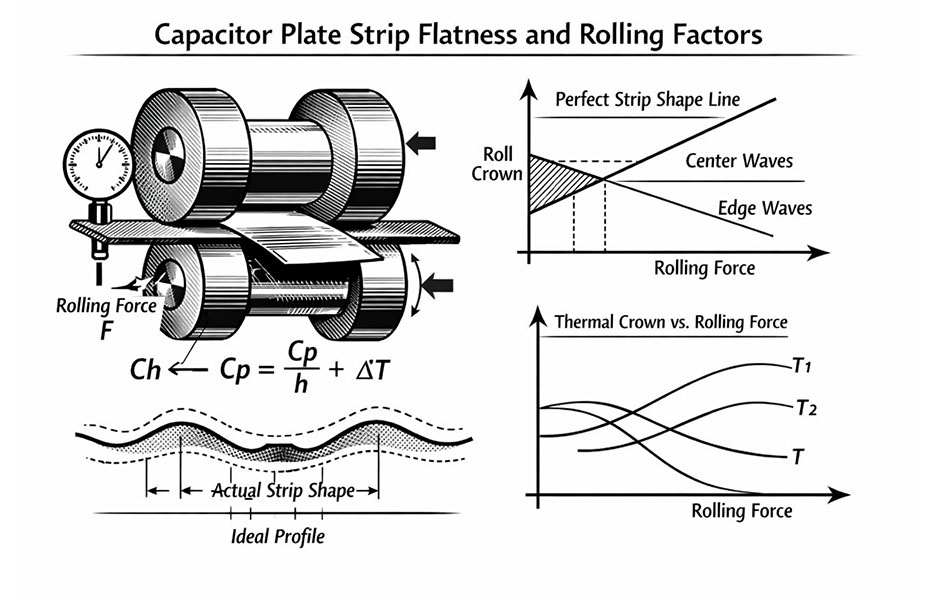

Plastic deformation of metal is uneven deformation. This unevenness will have a significant impact on the structural integrity of the material and the capacitor performance. An object is divided into many small grids, called coordinate grids (see Figure 1). If the height before deformation is H and the width is B, the height of each grid is H and the width is B, and the height of the deformed body after deformation is h and the width is b, and the height of any grid is h and the width is 6. The deformation condition of uniform deformation in the height direction is:

![]() (1)

(1)

The deformation condition in the width direction is:

![]() (2)

(2)

Figure 1 Coordinate grid

When an object undergoes uniform deformation, the deformation is not only uniform in the height direction, but also uniform in the width direction and longitudinal direction. Uniform deformation must simultaneously meet the conditions specified in Equations 5-7 and 5-8. In fact, in the plastic deformation of metals, whether it is rolling deformation, forging deformation, extrusion deformation, drawing deformation, etc., the deformation is uneven, which will bring many problems after deformation. In most cases, our work is to study the law of uneven deformation of metals during plastic deformation, improve the conditions of plastic deformation, make it as uniform as possible, reduce the adverse effects of uneven deformation, and thus improve the stability and consistency of the performance of XUANSN capacitors.

1 Main causes of uneven deformation

The main causes of uneven deformation include:

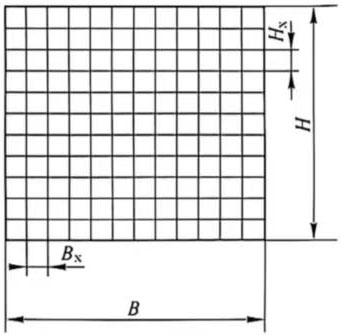

(1) External friction on the contact surface. Due to the action of external friction, the metal flow near the contact surface is difficult, such as causing the cylindrical forging to become a drum shape (see Figure 2). In this case, the deformed metal can be roughly divided into three areas: Zone I represents the difficult deformation area caused by external friction; Zone II represents the easy deformation area at an angle of about 45° to the external force; Zone III represents the free deformation area with a medium degree of deformation. Due to uneven deformation, secondary tensile stress is generated in Zones I and III. However, Zone I is mainly in a triaxial compressive stress state, so the secondary tensile stress in Zone I generally has no obvious effect. In Zone III, the secondary tensile stress changes the stress state, causing tensile stress in the circumferential (tangential) direction. Consequently, longitudinal cracks may form on the side surfaces during upsetting. This uneven deformation caused by external friction can affect the material’s density and structural stability to a certain extent, potentially impacting capacitor performance.

Figure 2: Effect of Friction on Deformation and Stress Distribution During Upsetting

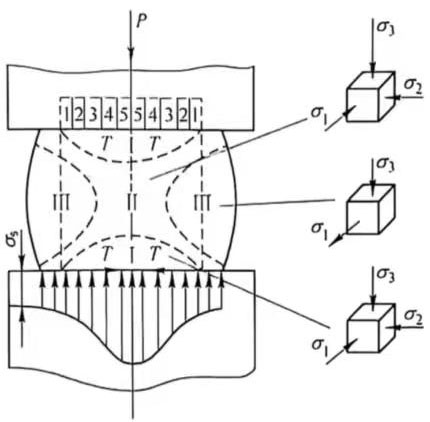

Due to the influence of external friction, the stress distribution on the contact surface is also uneven. During rolling, the friction mechanism of thick rolled pieces is similar to that of forging (see Figure 3). Zone I is the difficult deformation zone and has a conical shape. The metal in this difficult deformation zone does not undergo plastic deformation. Furthermore, the metal at the base of this cone does not slide relative to the roll surface, thus being called the contact zone. Zone II is the plastic deformation zone. This plastic deformation zone extends beyond the geometric deformation zone l. Compressive deformation of the metal progresses gradually from the surface of the rolled piece toward the center. Zones III and IV, due to the presence of rigid ends at both ends, experience longitudinal compression of the rolled piece, increasing in height. This uneven distribution of stress and deformation inside the metal not only affects the forming accuracy, but may also change the microstructure of the material, thereby potentially affecting the stability and consistency of the capacitor performance of XUANSN.

Figure 3 Schematic diagram of deformation during rolling

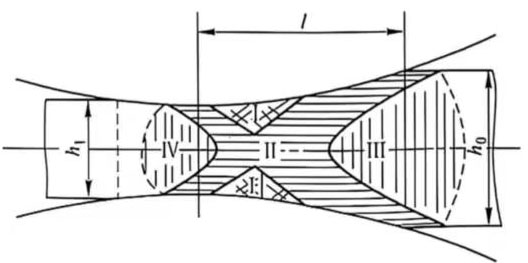

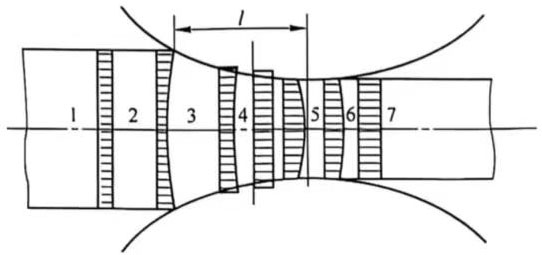

According to the relationship between the uneven distribution of metal flow velocity during rolling and the rigid ends of the rolled piece at the outlet and inlet, the deformation zone can be divided into seven zones (see Figure 4).

Figure 4 Schematic diagram of deformation zones of rolled piece

1 – rear rigid end zone; 2 – deformation occurrence zone; 3 – rear sliding zone; 4 – bonding zone;

5 – front sliding zone; 6 – deformation reduction zone; 7 – front rigid end zone

As can be seen from the figure, only on a vertical section in the bonding zone is the distribution of metal flow velocity in the height direction equal, and this section is called the neutral plane. Except for the neutral plane and the front and rear rigid end zones, the flow velocity of each layer of metal along the height of the rolled piece is uneven, which inevitably causes uneven deformation inside the metal.

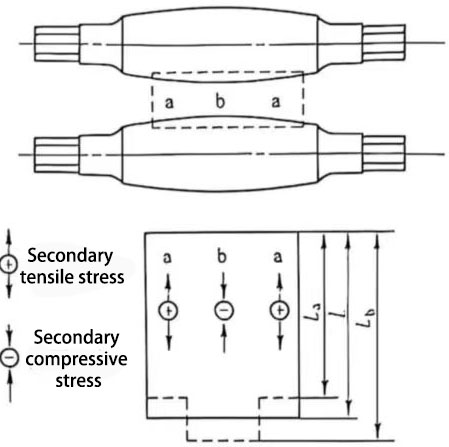

(2)The shape of the deformed object and tool. During the rolling process, a rectangular billet is rolled using a convex roller (see Figure 5). The deformation degree of the edge part a of the rolled piece is small, while the deformation degree of the middle part b is large. Because the rolled piece itself is a whole and its longitudinal extension tends to be consistent, the middle part will apply secondary tensile stress to the edge to reduce its extension. This stress difference also exists in the manufacturing of high-precision electronic components. If the stress distribution of the metal substrate is uneven, it will have an adverse effect on the conductivity and mechanical reliability of the capacitor performance.

Figure 5: The situation of a rectangular billet rolled by a convex roller

(3)The properties of the object are uneven. The chemical composition, structure and temperature distribution of the deformed object are inconsistent, which all affect the uneven distribution of deformation and stress. Taking the uneven temperature distribution as an example, the deformation resistance of the high-temperature part is small, and the deformation resistance of the low-temperature part is large. Under the same external force, the deformation stress generated by these two parts is different, thereby generating secondary stress. In addition, the uneven temperature distribution inside the object will cause uneven expansion, thereby causing secondary thermal stresses that are mutually balanced inside the object. As a result of the superposition of these two secondary stresses, larger secondary stresses may be generated in certain areas of the deformed object, which may cause the material with lower plasticity to break.

2. Possible consequences of uneven deformation and methods of reduction

In order to maintain its integrity, an object that produces uneven deformation generates secondary stresses. These secondary stresses are pairs of internal forces that are mutually balanced in the deformed object. According to the distribution of uneven deformation in the deformed object, secondary stresses can be divided into three types: secondary stresses that are mutually balanced in several large areas (several large parts) or at the macro level of the object are called the first type of secondary stress; secondary stresses that are mutually balanced in individual areas of the deformed object (between several grains) or at the micro level are called the second type of secondary stress; secondary stresses that are mutually balanced between the parts within a grain or at the atomic level are called the third type of secondary stress.

The secondary stresses in the deformed object will have the following effects on the plastic deformation process:

(1)Increase deformation resistance;

(2) Reduce plasticity;

(3) Presence of residual stress, which reduces product quality;

(4) Increase the technical complexity coefficient during the operation process.

Methods to reduce the impact of uneven deformation include:

(1) Rationally design the shape of processing tools, such as designing hot rolling rollers to a reasonable concavity and cold rolling and rolling to a reasonable convexity, to reduce the degree of uneven deformation of the metal, thereby improving the stability of the capacitor performance of XUANSN.

(2) Minimize the harmful effects of external friction, such as improving the surface finish of the tool and selecting a suitable lubricant.

(3) Select appropriate process parameters, such as deformation temperature, deformation speed, etc.

(4) Uniformly deform the structure and composition of the metal, such as high-temperature homogenization annealing of the ingot and intermediate annealing of the rolled piece.