In strip casting and rolling production, equipment failures often directly impact product quality and production efficiency, a critical issue for XUANSN, which prioritizes high quality. Proper equipment maintenance and management is not only fundamental to ensuring smooth production, but also essential for XUANSN to achieve high-quality production. This issue is particularly prominent in the production process related to Capacitor Process. However, this issue is so large and encompasses so many aspects that we will not discuss the entire equipment here. We will only focus on the impact and maintenance of the cast-roll sleeves, which are closely related to the production process. As mentioned earlier, cracks in the cast-roll sleeves can cause cracks on the plate surface. Blockages in the cast-roll sleeves can lead to poor plate shape and dimensional tolerances, uneven grain size, segregation, and plate sticking. Furthermore, cast-roll sleeves can sometimes break, disrupting the entire production process and preventing casting and rolling operations. Therefore, studying the working conditions of the cast-roll sleeves, improving the working conditions of the cast-roll sleeves, and extending the service life of the cast-roll sleeves are crucial issues for cast-rolling professionals.

1 Structure and Function of Casting Rollers

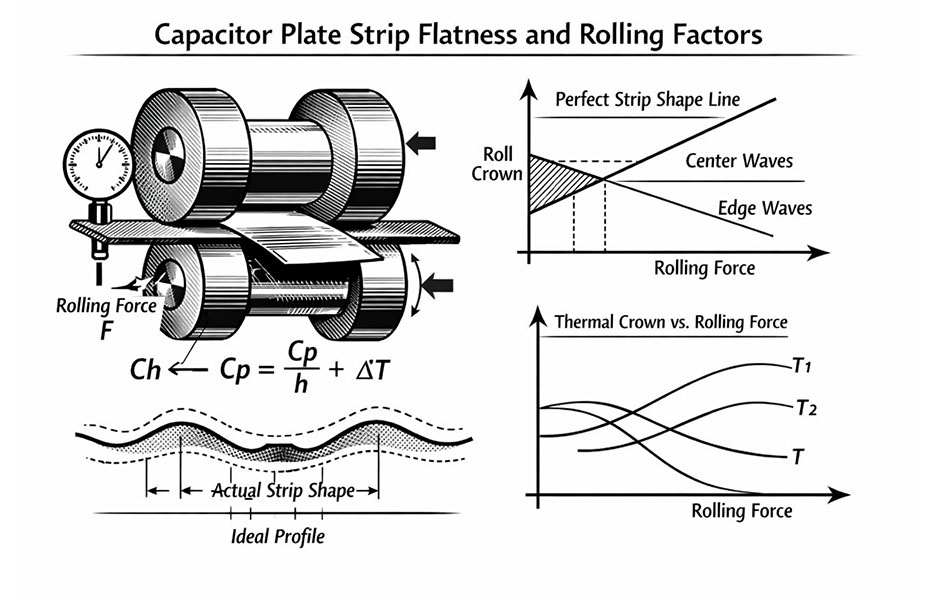

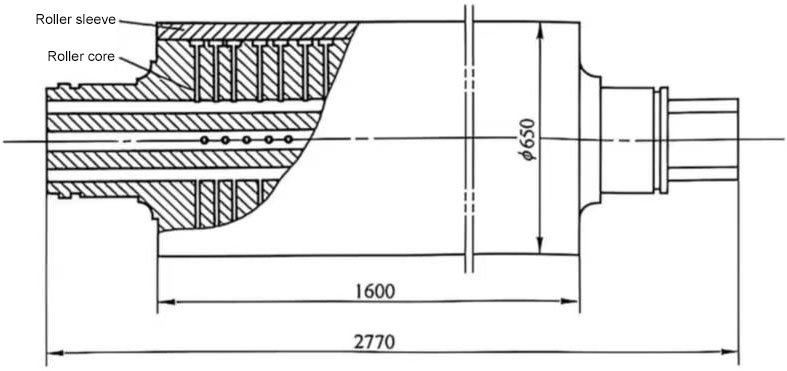

The casting roll is made of a hot assembly of a roll sleeve and a roll core with a substantial interference fit. The rolling assembly is shown in Figure 1. During the casting process, the casting roll surface contacts the molten aluminum, transferring the heat released by the molten aluminum to the cooling water flowing through the roll core, causing the molten aluminum to solidify rapidly. The solidified aluminum strip is then rolled, and the heat released during the rolling process is further conducted away, serving as both a crystallizer and a rolling element.This process has similar thermal control and structural stability requirements in material heat treatment and forming as those in capacitor Process.

Figure 1 Assembly diagram of casting rollers

2 Analysis of the stress state of casting roller sleeves

Casting roller sleeves bear the dual functions of casting and rolling. Their working conditions are extremely harsh and the stress state is quite complex:

(1)Thermal stress. It is well known that when the temperature of an object changes, the size of the object will expand and contract. If the object is in a free state and is heated evenly, the object will only change in volume without generating stress. However, during the casting and rolling process, the molten aluminum contacts the roller sleeve, reaching temperatures of around 700℃. The sleeve temperature, which peaks at around 500℃upon leaving the casting and rolling zone, gradually drops to around 100℃ due to cooling from the roller core’s cooling water and the surrounding environment. Upon re-entering the molten aluminum, its temperature rises again to 500℃. A cycle from 500℃ to 100℃ to 500℃ takes approximately 2-3 min. Each cycle involves dimensional expansion and contraction. This stress cycle is also particularly critical in casting and rolling production related to capacitor process As mentioned above, the roller sleeve is assembled to the roller core via an interference fit and is not subject to free expansion and contraction. Furthermore, a significant temperature gradient exists across the sleeve’s thickness (radial direction). The sleeve’s interior and ends are at their lowest temperatures, approaching the cooling water and ambient temperature, while the roller surface and the inward direction of the offset line are at their highest temperatures. This inevitably results in periodic thermal stresses within the sleeve in the radial, longitudinal, and circumferential directions.

The magnitude of thermal stress is related to the roller sleeve material, thermal conductivity, linear expansion coefficient, roller sleeve thickness, cooling water temperature, water pressure and surrounding environment. Thermal stress can be calculated by the following formula.

![]() (1)

(1)

Where E-elastic modulus;

∆T-temperature gradient;

a-linear expansion coefficient;

v-Poisson’s ratio.

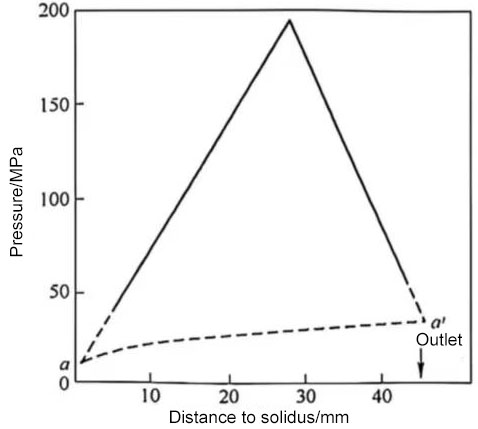

(2) Thermal shock stress. For a large Hunter casting mill, the pressure change in the rolling zone is approximately as shown in Figure 2. The rolling zone is impacted by heat and thermal alternating stress, while the non-rolling zone is not subjected to rolling force and is not subject to stress. The sleeve is subjected to the impact of sudden temperature changes and sudden increase or decrease in rolling force, which causes strong thermal shock stress to be generated on the roller surface in the radial and circumferential directions.

(3) Rolling stress, bending stress, and torsional stress. During the rolling deformation process, the roller applies a certain rolling force to the strip, and in turn, the strip also applies the same rolling force to the roller, generating rolling stress; at the same time, since the rolled strip needs to maintain a certain plate shape, the roller will be flattened and bent, generating bending stress; the roller rotates and rubs against the strip, generating torsional stress. Under the above forces, the roller sleeve is subjected to circumferential tensile stress, radial compressive stress, and axial bending stress. In the production of aluminum strips related to capacitor process technology, these stresses directly affect the surface quality and dimensional accuracy of the aluminum strips.

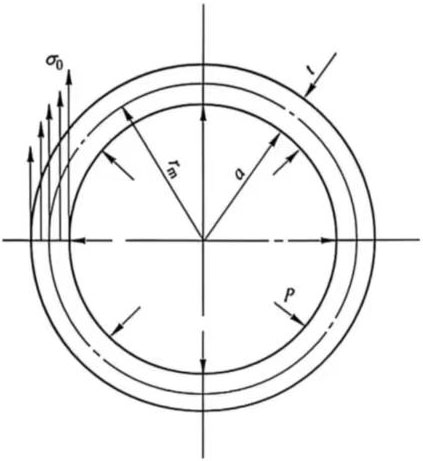

(4) Stress generated during the manufacturing process. The roller sleeve will generate residual stress and structural stress during the metallurgical, forging, machining, and heat treatment processes, and the interference fit between the roller sleeve and the roller core will also generate stress (see Figure 3). When purchasing roller sleeves, XUANSN will place strict requirements on stress control during the manufacturing process to avoid initial stress problems affecting subsequent use.

Figure 2 Pressure distribution calculated using the “straight edge approximation method” for a large Hunter casting and rolling mill (the bottom line aa’ shows the plane strain flow yield stress of the cast aluminum material in graphical form)

Figure 3 Schematic diagram of the expansion force of the roller sleeve after hot fitting

(5) Aluminum infiltration on the surface of the roller sleeve. The surface of the roller sleeve is in contact with the high-temperature aluminum melt. The aluminum will undergo certain physical and chemical reactions with the sleeve material, corroding the roller sleeve; during rolling, aluminum powder will adhere to the surface of the roller sleeve. With the cyclic and alternating changes of rolling, temperature, and time, aluminum will penetrate into the surface layer of the roller sleeve and react with the impurities at the grain boundaries of the roller surface steel to form new grain boundary materials with high temperature properties. At the same time, the volume of the grain boundary increases, generating structural stress, the grain boundary is destroyed, and expands into grain boundary cracks.

The thermal shock stress, thermal stress, and structural stress generated by surface aluminum infiltration cause cracks on the surface, which will be reflected on the surface of the strip as network-like grooves, seriously affecting the surface quality. Especially in capacitor process Under the condition that the process has extremely high requirements for surface uniformity and thin strip quality, the problem of aluminum infiltration of the roller sleeve must be focused on. The stress generated during the sleeve manufacturing process and the stress generated by excessive interference fit will also cause the roller surface to break along the axial direction, making the roller sleeve completely scrapped.

(6) The roller core groove is blocked. The cooling water contacts the roller sleeve through the roller core groove and takes away the heat released during the casting and rolling process. The cooling water contains various metal ions such as calcium and magnesium. During the heat conduction process of the cooling water, the concentration of calcium and magnesium ions becomes higher and higher, and precipitation occurs in the groove, blocking the groove. The cooling water is not able to flow smoothly, resulting in a serious imbalance in the surface temperature, which will cause the strip shape and size to exceed the standard, the grain structure to be uneven, and defects such as local sticking to the plate to occur. XUANSN has experienced product quality fluctuations due to roller core groove blockage many times during production, so groove cleaning has been included in the key maintenance link.

3 Maintenance and Management of Cast Roller Sleeves

The maximum thickness of cast roll sleeves is generally 50-60mm, and the minimum is 25-30mm. Excessive thickness reduces thermal conductivity, affecting production efficiency and the microstructure and properties of the strip. Excessive thickness reduces sleeve rigidity, making it difficult to control the strip size and shape. Roller sleeves must be replaced after a certain period of use. Therefore, maintenance management, such as drying, grinding, and cleaning, must be strengthened.

3.1 Hardness Requirements for Cast Roller Sleeve Materials

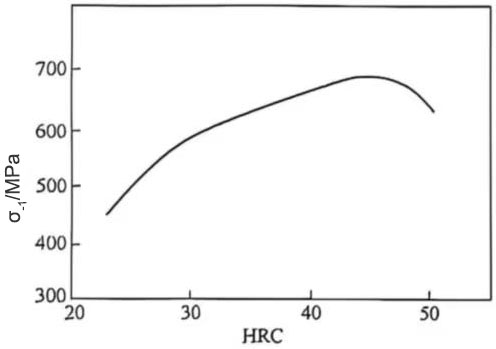

The relationship between the hardness and fatigue limit of roll sleeve materials is shown in Figure 4. As can be seen, lower hardness leads to lower fatigue limit. As hardness increases, the fatigue limit increases. When the hardness reaches approximately HRC 45, the fatigue limit reaches its maximum and then begins to decrease.

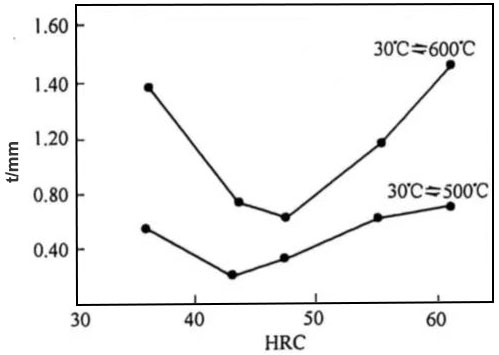

The relationship between crack depth and hardness during roll sleeve use is shown in Figure 5. Crack depth is shallow when HRC is between 40 and 50. Crack depth increases when HRC is <40 and HRC is >50.

Figure 4 Relationship between Fatigue Limit and Hardness

Figure 5 Relationship between crack depth and hardness

Therefore, HRC45 is the best hardness for the cast roller sleeve material. At the same time, the surface hardness unevenness should be controlled within HRC±2. This is to meet the capacitor process requirements for stable production of high-quality aluminum strips.

3.2 Baking of cast roller sleeves

In order to ensure that the cast roller sleeves can reliably transmit torque during the casting process, a hot-fitting interference fit process must be used to assemble the sleeves onto the roller core to ensure a tight fit between the sleeves and the roller core. The interference fit is calculated and selected based on the sleeve material, the torque to be transmitted, and the minimum thickness of the sleeve. Different interference fits produce different expansion forces on the sleeves, and the expansion force is calculated by the following formula:

![]() (2)

(2)

Where E-elastic modulus;

F-baking interference fit;

D-roller core outer diameter;

d-roller sleeve inner diameter.

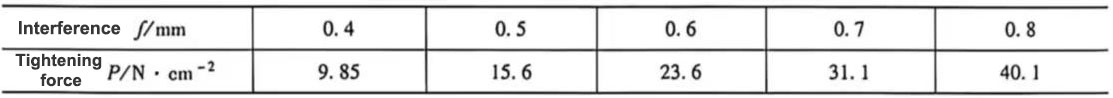

The relationship between interference and expansion force can be calculated using Equation 2. For the φ650mm casting mill used by XUANSN, the relationship between interference and expansion force is shown in Table 1.

Table 1 Relationship between interference and expansion force

If the interference is too large, the hot-loading stress will increase, which will accelerate the damage of the roller sleeve and may even cause the sleeve to break along the axial direction; if the interference is too small, the roller sleeve and the roller core may move relative to each other, and the torque cannot be effectively transmitted. Therefore, the interference should be reasonably selected according to the material strength and the size of the rolling torque. This selection is particularly critical in the casting and rolling production related to capacitor process. For general medium and high strength steel, the interference can be selected according to the following empirical formula:

![]() (3)

(3)

Where DInside is the inner diameter of the roller sleeve.

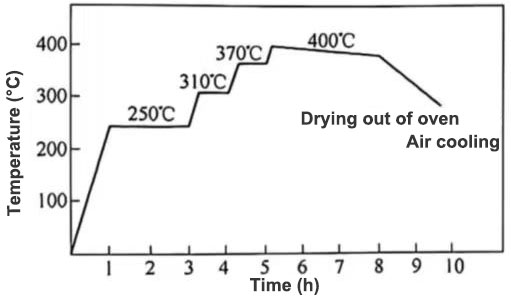

The cleaned roller sleeve is placed in a heating furnace for heating. The heating temperature, heating time, and cooling method will have a direct impact on the sleeve life. The heating temperature should ensure that the roller sleeve has sufficient expansion, but should not exceed 400℃. The heating rate should not be too fast, and after hot loading, it should be gradually cooled under insulation conditions. Its heating curve is shown in Figure 6.

3.3 Grinding of Cast Roller Sleeves

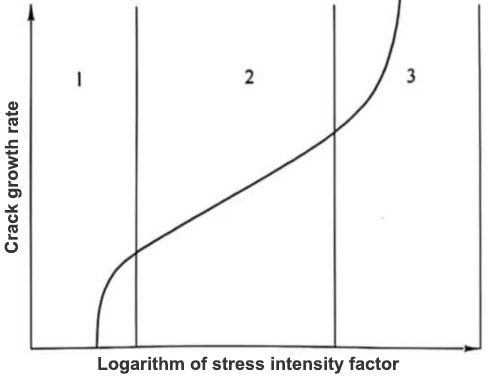

As mentioned above, during the production process, cast roll sleeves are subjected to significant stress, which can cause surface cracks. This directly impacts the surface quality of the strip during the subsequent cold rolling process, resulting in holes and breakage in the foil. Regular turning is essential. Based on the development trend of cast roll cracks (Figure 7), XUANSN stipulates that the turning and grinding period should be carried out before it develops to the third stage, and the turning depth should be the depth of the turtle crack + 0.3~0.5mm.Combined with the strict requirements of capacitor Process, this measure can effectively guarantee material performance and product quality.

Figure 6 Sleeve Drying Heating Curve

Figure 7 Typical Crack Extension Diagrams: 1 – Deceleration Creep Stage; 2 – Acceleration Creep Stage; 3 – Rapid Acceleration Creep Stage

After turning, the rolls are ground to the required crown and roughness. After grinding, the roll surface must be inspected for residual cracks before use.

3.4 Cleaning of Cast Roll Cores

In areas with high water hardness, the water contains high levels of calcium and magnesium ions and small amounts of iron and silicon. The cooling water is heated within the sleeve, causing the temperature to rise, which can cause cracks. Substances such as CaCO3, MgCO3, Fe2O3, and SiO2 deposit in the grooves of the roller core, increasing resistance to cooling water flow and reducing the cooling effect of the roller surface. Over time, some grooves can become completely blocked, causing a sharp rise in temperature in certain areas of the roller surface. This temperature difference can reach 80-90℃, seriously affecting strip shape and surface quality, and even causing premature failure of the roller sleeve. In capacitor process related production, these cooling issues can also affect product performance. Therefore, XUANSN has formulated a strict cleaning system: using 5% dilute hydrochloric acid with corrosion inhibitors and passivators, the rollers are regularly pressure-cycled cleaned to ensure that the cooling water channels are unobstructed.