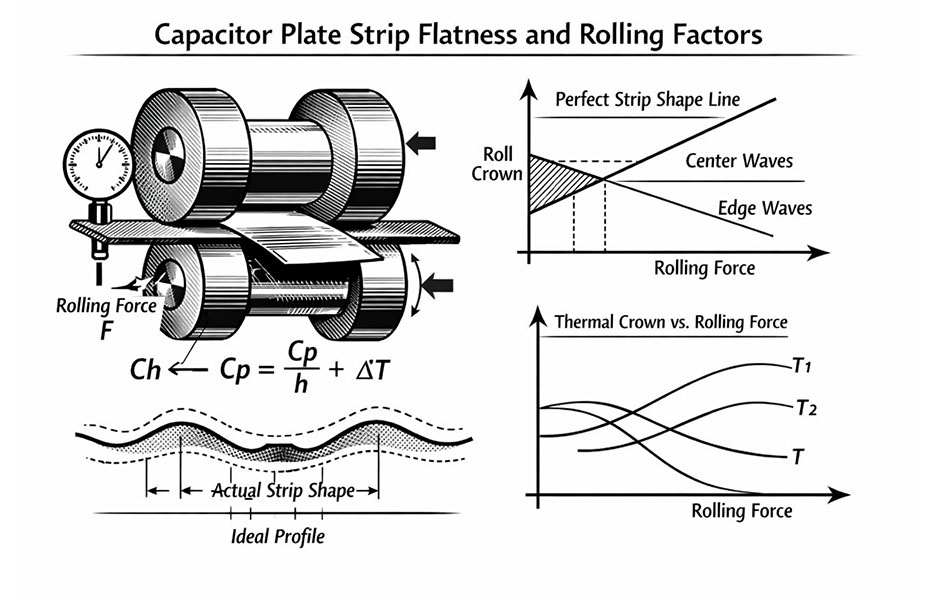

(1) Coarse Grains. Coarse grains often manifest as wheat-ear crystal structure. As mentioned above, due to the lack of active crystal nuclei in electrolytic aluminum liquid and superheated aluminum melt, the energy of homogeneous nucleation is higher than the energy of nucleation on the surface of the casting roller sleeve. Therefore, during the casting process, when the aluminum liquid contacts the water-cooled casting roller sleeve, spherical crown-shaped crystal nuclei are formed on the roller surface. Because the cooling rate of casting is very high, it has a strong directional heat conduction effect. Therefore, based on the spherical crown core, it quickly grows into wheat-ear-shaped grains with strong directionality (see Figure 1). This coarse grain phenomenon will affect the capacitor quality, because the uneven or too strong directionality of the grain structure inside the plate will have an adverse effect on the performance of the capacitor during subsequent processing and use.

Figure 1 Low-magnification structure of cast plate – wheat grain

Causes: The quality of the modifier is poor and there is no modifier effect; the electrolytic aluminum liquid is not strictly cooled and nucleated, or the temperature is not controlled, so that the aluminum liquid temperature exceeds the overheating temperature; the modification process is unreasonable, the time of adding the modifier is too long, the modification effect is attenuated, or the addition temperature is too low, the modifier is not fully dissolved and diffused evenly, and cannot fully play its role. Add a certain amount of solid material to the melt to improve the melt quality; appropriately increase the amount of modifier or replace the modifier, etc. to improve the fine-grained structure.

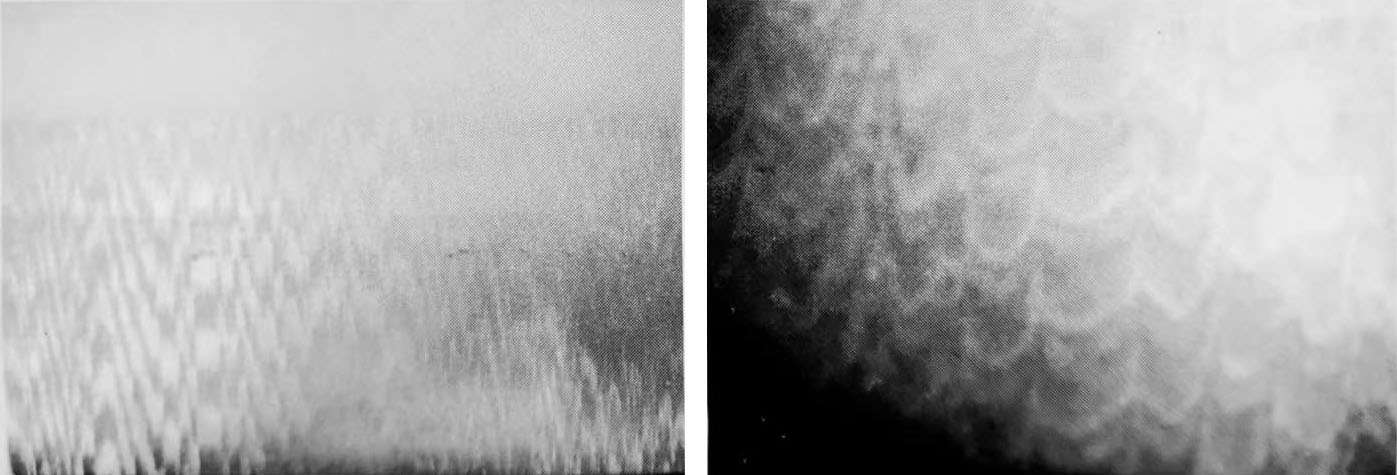

(2)Uneven grains. One side is large grains, the other side is small grains; sometimes coarse and fine grain bands appear, and large and small grain areas coexist on the plate surface (see Figures 2 and 3).

Figure 2 Macrostructure of cast-rolled plate

Figure 3 Cross-sectional structure of cast-rolled plate – uneven grains

Causes: The diameters of the upper and lower rollers are different, resulting in differences in thermal conductivity; the modifier is not fully dissolved and unevenly distributed; the nozzle diversion is unreasonable, resulting in uneven temperature; the grooves of the roller core are blocked, the cooling water flow is not smooth, and the surface temperature is uneven.

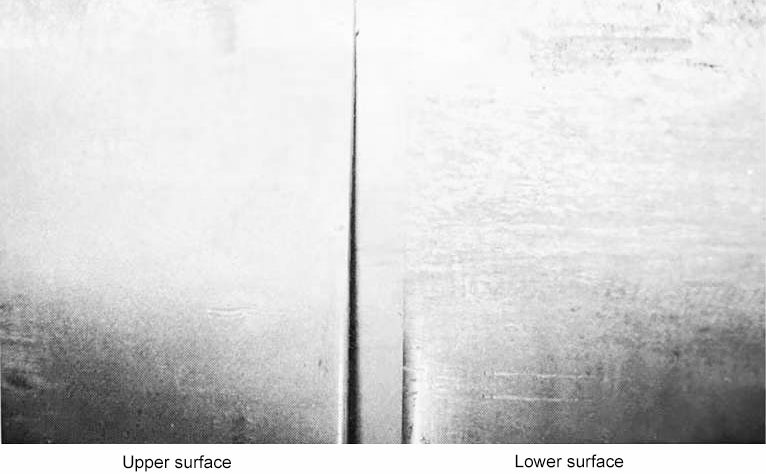

(3)Delamination caused by low-melting-point impurities such as iron and silicon appears below the surface of the cast-rolled strip. This delamination extends to the surface, and cracks are called cracks. The surface of the strip is not cracked, which is called delamination (see Figure 4). The surface and inner sides of the delamination have large differences in structure. The surface side has less low-melting-point substances and coarser grains; the inner side has more low-melting-point substances and finer grains. In the subsequent cold processing, due to the difference in grain structure, tiger-skin stripe patterns will appear. This type of delamination defect will directly affect thecapacitor quality, because the internal structure of the plate is uneven or the low-melting-point substances are aggregated, which will cause unstable performance or defects during capacitor manufacturing and use.

Figure 4 Strip layering

Cause of formation: As mentioned above, when the aluminum melt contacts the internally cooled roller surface, it solidifies into a hard shell and shrinks. A small gap appears between the hard shell and the roller surface, the thermal resistance increases, and the temperature rises. The low-melting phase aggregation area melts, and under the tensile stress and shear stress of casting and rolling, cracks are generated due to low strength. However, the internal melt is immediately replenished and fills the cracks. After deformation in the rolling zone, there will be no crack marks on the surface, but due to the difference in its structure, it is severely delaminated, and light and dark tiger stripes appear on the surface of the strip; when the delamination is lighter, the surface of the cast strip is not obvious, but tiger stripes will be left on the plate surface during the subsequent cold rolling process.

(4)Slag inclusion. The cast strip contains slag, flux, refractory fragments, metal and non-metal oxides, etc., which are collectively called slag inclusions. Slag inclusions destroy the continuity of the metal and affect the structure and performance of the material, but slag inclusions are difficult to completely remove. The low-magnification structure of general products does not allow the presence of slag visible to the naked eye. For high-grade plates and strips and double-zero raw materials, the slag content should be as low as possible and the slag particles should be as fine as possible. Especially for double-zero raw materials, large slag particles may produce pinholes, which directly affect the capacitor quality. Therefore, doing a good job of refining and filtering to reduce slag inclusions is one of the most important issues facing aluminum processing technology.

(5) Air channels. Holes that extend longitudinally or intermittently in the cast strip are called air channels, and holes that are invisible to the naked eye are called micropores (see Figures 5 and 6). Air channels may extend for tens of meters, or even as long as the entire coil and several coils. Air channels are malignant defects and are absolutely waste products.

(6) Center segregation. In the center of the thickness direction of the cast strip, a large number of iron, silicon and other compounds gather, and even excess, low-melting-point imbalance compounds appear. After etching in an alkaline solution of a certain concentration for a certain period of time, a continuous line or intermittent continuous lines will be observed at the center of the strip (see Figures 7 and 8). These compounds are mostly hard and brittle phases. Excessive concentration can affect the material’s processing, physical and chemical properties, and mechanical properties, potentially adversely affecting capacitor quality.

Figure 5: Airway (cross-section)

Figure 6: Airway (surface)

Figure 7: Central segregation (microstructure)

Figure 8: Central segregation in 1050 alloy (macrostructure)

Figure 9: Central segregation in 8011 alloy (macrostructure)

Figure 8 shows that the central segregation in 1050 alloy is a thin line and very minor. Generally, it does not significantly affect the material’s processing and mechanical properties. However, when central segregation is severe in alloys such as 8011, 3003, and 1100, a large concentration of low-melting-point compounds occurs, adversely affecting the production of certain high-quality products. Therefore, it must be controlled.

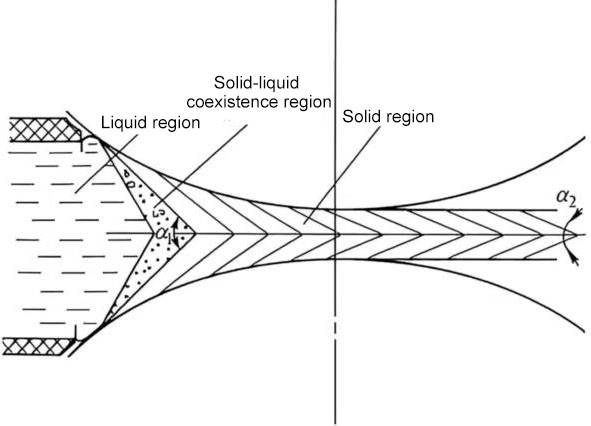

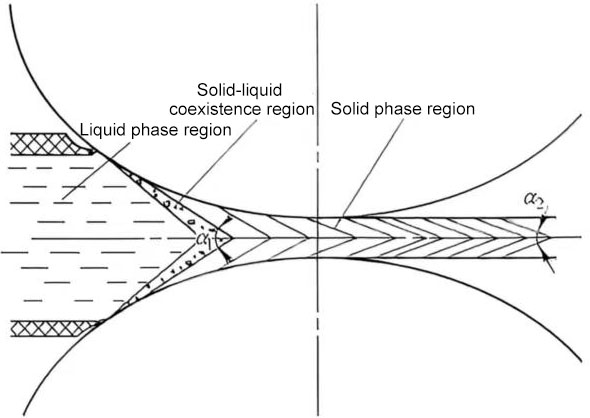

Cause: During melt crystallization, crystal growth always prioritizes heat conduction. As mentioned earlier, the vast majority of heat released during the casting and rolling process is conducted through the roller sleeves to the internal cooling water, which removes it. The cooling rate during casting and rolling is very high, reaching approximately 100°C/s. Consequently, the degree of undercooling during crystallization is significant, far from the equilibrium crystallization state, making it very prone to segregation and accumulation of impurities and low-melting-point substances. The most favorable direction of heat conduction is always the normal to the roller surface, and crystal growth also follows this normal. The melt near the roller surface crystallizes first, while the melt farther from the roller surface, i.e., the center of the cast plate, crystallizes last (see Figures 10 and 11). Greater cooling intensity, faster casting and rolling speeds, greater undercooling, deeper liquid pockets, and smaller product angles in the cast plate, further from the equilibrium crystallization state, more impurities and low-melting-point substances accumulate in the center, and more severe center segregation. Therefore, impurity content, low-melting-point substances, cooling intensity, and casting and rolling speed are key factors influencing center segregation. The impurity content and low-melting-point substances are determined by the alloy. Once an alloy is determined, its composition can only be adjusted within a specified range; fundamental changes are not possible. Therefore, center segregation can only be controlled by adjusting the cooling intensity and casting speed. Practice has shown that appropriately increasing the cooling water temperature and controlling the casting speed within a certain range can significantly reduce the degree of center segregation (see Figure 12), thereby improving capacitor quality.

Figure 10: Crystallization diagram at higher cooling water temperature and lower casting speed

Figure 11: Crystallization diagram at lower cooling water temperature and higher casting speed

Figure 12: Center segregation of 8011 alloy at different cooling water temperatures and casting speeds

Top two samples: water temperature 32°C, casting speed 900 mm/min;

Bottom two samples: water temperature 22°C, casting speed 1200 mm/min

Figure 12 shows that, under the same corrosion conditions, when the cooling water temperature is appropriately increased and the casting speed is reduced, the center segregation line (dot) is no longer visible. However, when the cooling water temperature is lower and the casting speed is higher, the center segregation line (dot) becomes clearly visible. Admittedly, under current casting and rolling conditions, due to the sharp-angled front of the crystallization zone, center segregation cannot be fundamentally resolved or eliminated. It can only be controlled to a certain extent to ensure material structural uniformity and thus improve capacitor quality.