1 Quality inspection of casting and rolling process in capacitor foil rolling

When the casting and rolling process is normal, the plate is inspected for quality. This operation is particularly important in capacitor foil rolling production.

Chemical composition inspection: After the chemical composition adjustment is completed, take a sample from each furnace door in the mixing furnace for analysis. Qualified samples are taken out of the furnace, unqualified samples are readjusted, and resampled and analyzed until qualified. In the production process, each time the furnace is turned over, it is necessary to refine in the static furnace, and then sample and analyze the chemical composition in the furnace or launder, and use this as the factory standard.

Gas analysis: After refining and standing, gas analysis is carried out as soon as it comes out of the furnace. If it meets the standard requirements, if it does not meet the standard requirements in formal production, it will be immediately supplemented with refining and reanalyzed until it meets the standard. The measurement frequency should be increased in the rainy season. It is best to spot check once every 4 hours. If the detection exceeds the standard, refining should be carried out immediately. If the gas content does not decrease after refining, and sometimes even increases, the oxygen and water content of the gas refining system should be checked. If the water and oxygen content exceeds the standard, deep deoxidation and dehydration treatment should be carried out, and then degassing refining should be carried out. These gas control requirements also apply to the process of capacitor foil rolling.

Grain inspection: Cut a plate of about 150mm and corrode it with a mixed solution of HF+HCI+HNO3, or use an alkaline solution of about 25% to corrode it. After corrosion, rinse it with clean water and check the grain size.

Surface quality inspection: Carefully check the surface of the cast and rolled strip for cracks, airways, inclusions, sticky plates, hot strips, fractures, etc., and deal with problems in time. The surface quality requirements of capacitor foil rolling products are extremely high, so this inspection must be strengthened.

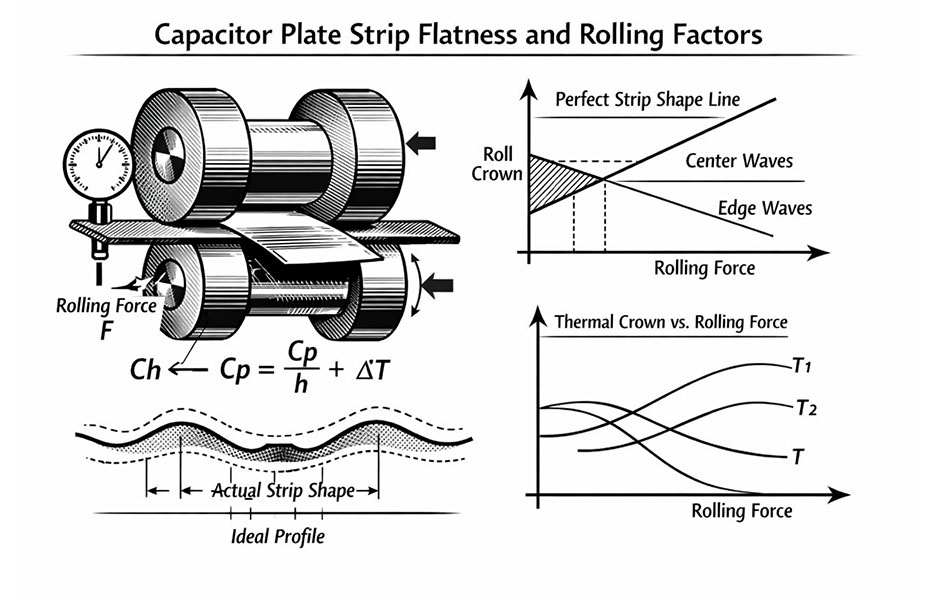

Plate shape inspection: The plate shape here refers to the dimensional deviation on the cross section of the strip. The bad strip enters the coiling stage under normal tension. After the casting and rolling process, surface quality, strip width, etc. are all normal, the abnormal plate bad part is cut off, and then N pieces of plates of about 150mm are cut and numbered in sequence; the sum of the length dimensions of each piece is equal to or slightly greater than the circumference of the outer diameter of the casting and rolling roller. For each plate, 50mm from both sides, the middle is evenly divided into sections, each section is about 100mm, the transverse dimensions are measured, and the same plate difference and convexity are detected (see Figure 1). The same plate difference and convexity should be controlled within the internal control standard range. Generally, the same plate difference should be controlled within 0.03mm, the convexity should be controlled within 1%, and it is best to control it between 0.2% and 0.7%; the convexity is not allowed to be 0, and negative convexity is not allowed. In the capacitor foil rolling, plate shape control directly affects the thickness uniformity and subsequent performance stability of the product.

Figure 1 Measurement method of plate difference and center convexity

Center convexity: the percentage of the difference between the middle thickness and the average thickness of the two sides on any cross section of the strip relative to the middle thickness. The center convexity is generally calculated according to formula 1:

=-x100%Ho·61.(1)

Wherein, H0-center thickness, that is, the maximum thickness value measured within 100mm on both sides of the center point on the cross section of the strip, mm;

H1, H2-edge thickness, that is, the thickness at 50mm from the two sides on the cross section of the strip, mm.

Same plate difference: the ratio of the absolute value of the thickness difference between two points symmetrical to the center along the width direction on any cross section of the strip to the thickness of the center point (except for the measurement points H1 and H2 on the two sides). The same plate difference is generally calculated according to formula 2:

00%Ho(2)

Where Hn1, Hn2-thickness of any two points symmetrical to the center point H0 (i.e., equidistant from the center point L), mm;

H0-thickness of the center measurement point, mm.

In normal production, a piece of plate of about 150mm is cut from each roll, and the plate shape is checked according to the above regulations.

2 Size deviation

Size deviation includes:

(1) The same plate difference exceeds the standard, which means that the thickness difference on both sides of the belt is large, forming a wedge-shaped plate.

(2) The roll gap on both sides is inconsistent, one side is large and the other side is small; the casting nozzle is deformed, and the lip opening forms a wedge shape (see Figure 2, due to the unbalanced pressure of the two hydraulic cylinders).

Figure 2 The lip opening of the casting nozzle is large on the left and small on the right

(3) There is a deviation in the thickness of each point in the transverse direction, which exceeds the standard range. The thickness of the roller sleeve may be too thin, exceeding the allowable use value. Or the nozzle structure is unreasonable, the liquid flow is unevenly distributed, and there is turbulence; the uniform distribution of cooling water is destroyed, resulting in unbalanced surface temperature and excessive size of the plate surface.

(4) The center convexity exceeds the standard. The difference between the thickness of the middle part of the strip and the thickness of any side is less than or equal to 0 or greater than 1% of the strip thickness. Causes: The roller convexity is too large or too small; the sleeve is too thin; the coiling tension is too large or too small, and the casting temperature is too high or too low.

(5) The longitudinal thickness of the slab exceeds the tolerance. There are two situations: 1) Its thickness changes periodically, and the length of one cycle is basically equal to the circumference of the casting roller; 2) There is no specific location and section for the thickness change, and there is no regularity to follow. The cause of the former is relatively obvious, and there is a problem with the equipment: the cooling system inside the roller sleeve is partially blocked, and the bearing box fails, etc. The reasons for the latter are more complicated: the process may be unstable, the casting and rolling temperature, speed, cooling intensity, coiling tension, and the front box liquid level may change too much; the roller sleeve thickness is thin, the sleeve and the core are not tightly combined, and there is a small gap. During the casting and rolling process, the roller sleeve may undergo irregular elastic changes, resulting in irregular changes in the strip thickness. Therefore, in the process of capacitor foil rolling, it is necessary to comprehensively optimize the rolling process and equipment parameters to improve the stability of the slab thickness.