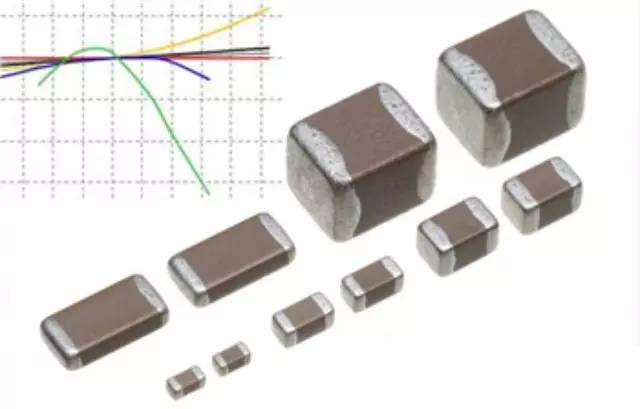

The Multilayer Chip Ceramic Capacitor (MLCC) are mainly divided into two major categories: paraelectric (class I) and ferroelectric (class II). Below them, there are many kinds of different temperature and characteristic laws, and the specific values are different. Media material. The dielectric constants of these two types of dielectric materials change with temperature, but the magnitude and regularity of the two kinds of dielectric materials are completely different. For this reason, EIA has developed “class I ceramic dielectric temperature coefficient” and “class II porcelain dielectric temperature characteristics” Set of capacity-temperature characteristics standards.

In practical applications, mainly the following three materials

(1) Doping modification of strontium zirconate SrZrO3, mainly manufacturing NPO (COG) MLCC

The electrical properties of this material MLCC are quite stable and hardly change with temperature, voltage, frequency and time:

The capacity change rate is -0±30ppm/°C from -55°C to 125°C;

The change in capacitance with frequency is less than ±0.3 ΔC;

The drift or hysteresis of the capacitance is less than ±0.05%;

The change in capacitance relative to the service life is less than ±0.1%;

The NPO (COG) MLCC is suitable for a variety of circuits, including high frequency circuits for stability requirements, and is commonly used for oscillators, tank tank capacitors, and coupling capacitors in high frequency circuits.

RF capacitors made by optimized design can be used up to 3 GHz, of which ATC is the RF-MLCC benchmarking company.

(2) Barium titanate BaTiO3 doping modification, is the main material for the manufacture of X7R, X5R MLCC products

Because the capacity that NPO(COG) MLCC can achieve cannot meet the requirements of the circuit for larger capacitance, such strontium titanate-based X7R and X5R MLCCs have been developed. Its capacity can be made larger under the same volume, X7R, X5R MLCC capacity can be very high, up to 100uF.

This material has poorer stability than NPO(COG)MLCC. The capacity of X7R and X5R MLCC varies with voltage, frequency conditions and time:

There is a DC bias characteristic, that is, when a high DC voltage is applied across the capacitor, its effective capacity is reduced;

The capacity change rate is +15% from -55 ° C to 125 ° C, and the curve is non-linear;

Changed by about 1% ΔC every 10 years, showing a change of about 5% in 10 years;

X7R and X5R MLCCs are widely used in non-high frequency circuits and are the largest type of capacitors, accounting for more than 60% of the total MLCC market.

(3) Barium titanate BaSrTiO3 doping modification, is the main material for the manufacture of Z5U, Y5V MLCC products

This type of material was developed to achieve greater capacity than the X7R and X5R MLCCs. This material can achieve high capacity and low cost per unit capacity.

Z5U and Y5V MLCCs have poor stability, are sensitive to temperature and voltage, and have a narrow temperature range:

-30 ° C ~ 85 ° C capacity change + 22% ~ -82%;

There is a strong DC bias characteristic;

High loss, up to 5% or even larger;

Despite its unstable capacity, it can achieve a capacity level that can replace electrolytic capacitors, and has a certain range of applications, mainly in the application of decoupling circuits.

In recent years, due to the development of X7R/X5R product manufacturing technology, the capacitance obtained by continuously reducing the film thickness of X7R/X5R MLCC dielectrics is close to the capacitance level of Y5V/Z5U MLCC. However, due to the large grain size, the Y5V/Z5U material cannot be further reduced in thickness and cannot effectively develop higher capacity products. In addition, the Y5V/Z5U materials have problems of large loss and poor reliability, so the Y5V/Z5U has gradually been eliminated.

Chip capacitor purchase

The parameters to be provided in the selection of Multilayer Chip Ceramic Capacitor are size, required accuracy, voltage requirements, capacity values, and further requirements for loss, porcelain strength, and DC bias characteristics.